Why Manufacturing Companies Switch from SAP to Odoo: Cost, Speed, and Flexibility That Actually Matters

The manufacturing sector is at an inflection point. For three decades, SAP was synonymous with “enterprise ERP”—the system that Fortune 500 companies used, the platform that “serious” manufacturers implemented. But in 2026, that narrative is crumbling.

Why? Because the business environment has fundamentally changed, and SAP hasn’t kept pace.

Manufacturing today operates in a world of compressed timelines, volatile supply chains, labor shortages, and relentless pressure to innovate. Companies that once could tolerate an 18-month ERP implementation now need transformation in months.

Businesses that could absorb SAP’s multi-million-dollar price tag now demand transparency and predictable ROI. Leaders expecting rigid “best practices” now need flexibility to compete on their own terms.

The result: A historic shift. Manufacturing companies across Asia, Europe, and North America are making the calculated decision to migrate from SAP to Odoo—not out of desperation, but out of strategic clarity.

According to Grand View Research, the global ERP market is projected to reach $78.4 billion by 2026, with cloud-based, modular platforms capturing the fastest growth segment.

Simultaneously, 7 million+ users rely on Odoo worldwide, including leading manufacturers in automotive, food & beverage, pharmaceuticals, and industrial equipment.

This blog post answers the question manufacturing CFOs, CTOs, and operations directors are asking right now: Is it actually time to switch from SAP to Odoo? What’s the real financial impact? Can we really go live in weeks instead of years?

The answer is nuanced, data-driven, and often surprising.

Key Takeaways

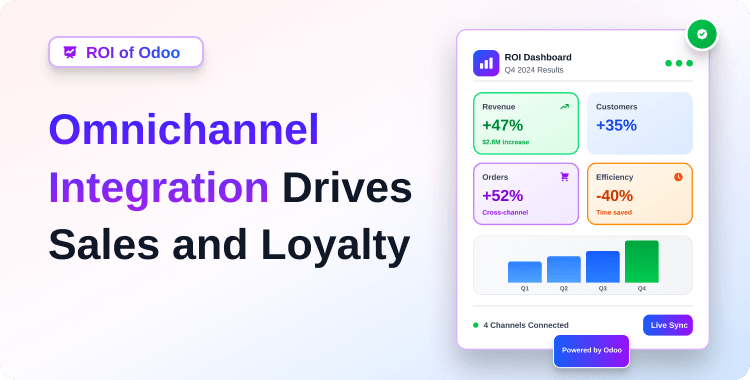

- TCO Reality Check: SAP’s total cost of ownership is 5-10 times higher than Odoo, with implementation costs reaching $100K-$500K+ annually.

- Speed Wins: Deploy Odoo in 4-6 weeks vs. SAP’s 12-24 month implementation marathons.

- Modular Beats Monolithic: Odoo’s plug-and-play architecture adapts to change; SAP locks you into rigid processes.

- Real Savings: Manufacturing companies report 30% faster order processing and 10-30% production cost reductions.

- Future-Proof Flexibility: Nearly 7 million users worldwide are already leveraging Odoo’s cloud-native, AI-ready architecture.

- Expert Partnership: HasTech IT Ltd brings certified Odoo expertise and Bangladesh market knowledge to accelerate your ERP transformation.

The ERP Landscape in 2026: Why Legacy Doesn’t Work Anymore

Enterprise resource planning has evolved. What qualified as “best practice” in SAP’s monolithic design is now a liability.

SAP’s Original Promise (1990s–2000s):

- Centralize all business data

- Standardize processes across the organization

- Build an impenetrable wall around data security

- Become “enterprise-grade” by implementing at a massive scale

The Reality Today (2026):

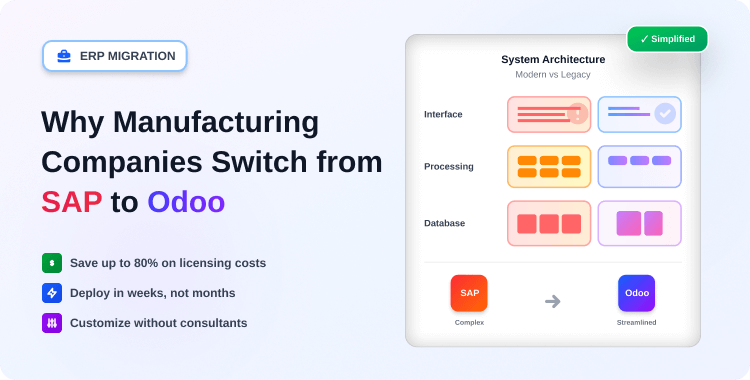

- Monolithic architecture is too rigid for rapid market changes

- Standardized processes stifle competitive differentiation

- Data centralization now introduces single-point-of-failure risks in distributed supply chains

- “Enterprise-grade” now means cloud-native, AI-ready, and continuously updated—not massive, complex, and expensive

Odoo’s Philosophy (Built for 2026):

- Modular, composable architecture that evolves with your business

- Plug-and-play modules that activate only when needed

- Cloud-native foundation with AI, automation, and real-time analytics built in

- Continuous monthly updates, not disruptive annual mega-upgrades

For manufacturing specifically, this distinction is critical. You don’t need to mandate that all suppliers use your data structure. You need to integrate with their systems.

You don’t need to force every plant to operate identically. You need global visibility with local flexibility. You don’t need to wait 12 months for a feature update that solves an urgent production problem. You need it deployed in weeks.

SAP forces the first model. Odoo enables the second.

The Cost Reality: Why SAP’s Price Tag Doesn’t Match Its Value

Let’s talk money, because CFOs care about numbers.

The True Cost of SAP: Beyond Licensing

Year 1 Costs (Implementation Year):

- Software licenses: $100,000–$500,000+

- Implementation consulting: $500,000–$2,000,000+ (SAP projects frequently exceed budgets)

- Hardware/infrastructure: $100,000–$300,000

- Training and change management: $100,000–$300,000

- Year 1 Total: $800,000–$3,100,000+

Annual Ongoing Costs (Year 2+):

- Annual license renewals: $100,000–$500,000

- Support and maintenance (typically 17–20% of license cost): $50,000–$150,000

- Version upgrades (every 3–5 years, $200,000–$1,000,000+)

- Mandatory customization fixes for each upgrade: $50,000–$500,000

- Annual Total: $200,000–$1,150,000

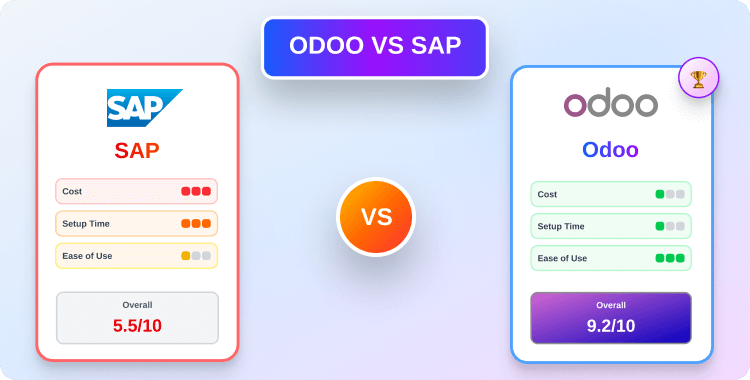

5-Year Total Cost of Ownership (SAP): $2.6M–$7.8M.

The Odoo Alternative: Transparent, Predictable, Scalable

Year 1 Implementation:

- Odoo Cloud subscription (200 users at $25/user/month): $60,000/year

- Implementation services (4–6 week engagement): $50,000–$150,000

- Training and change management: $20,000–$50,000

- Year 1 Total: $130,000–$260,000

Annual Ongoing Costs (Year 2+):

- Cloud subscription renewal: $60,000–$120,000 (as you add users/apps)

- Support and optimization: $10,000–$30,000

- Updates (continuous, included): $0

- Customizations (as needed): $10,000–$50,000/year

- Annual Total: $80,000–$200,000

5-Year Total Cost of Ownership (Odoo): $390,000–$1,000,000

The Numbers Don’t Lie.

Metric SAP Odoo Savings Year 1 Implementation $800K–$3.1M $130K–$260K 84–92% less Annual Costs (Ongoing) $200K–$1.15M $80K–$200K 60–83% less 5-Year TCO $2.6M–$7.8M $390K–$1M 85–95% less Per-User Monthly $270–$625 $24.90 96% less

For a mid-market manufacturer with 200 users, this translates to:

- SAP investment: $3–4M over 5 years

- Odoo investment: $500K–$700K over 5 years

- Direct savings: $2.3–3.5M

Add in opportunity cost (faster ROI with Odoo, value creation starting in month 2–3 instead of month 18–24), and the financial case becomes overwhelmingly clear.

Speed & Implementation: Why Timeline Matters in 2026

Implementation speed isn’t a luxury—it’s a competitive necessity in 2026.

SAP Implementation: The 18-Month Marathon

A typical SAP S/4HANA implementation follows this pattern:

Phase 1: Planning & Design (Months 0–3)

- Workshops to “standardize” your processes to SAP’s model

- Change management planning (often insufficient)

- Hardware procurement and infrastructure buildout

- Consultant armies ramping up

Phase 2: Build & Customize (Months 4–12)

- Configuration of modules

- Custom development for processes SAP won’t support natively

- Integration with legacy systems

- Lengthy user acceptance testing (UAT)

Phase 3: Data Migration & Cutover (Months 12–18)

- Clean and transform legacy data

- Parallel testing with old and new systems

- High-risk cutover weekend

- Post-go-live stabilization (often 3–6 additional months)

Reality: Most SAP implementations miss timelines by 20–50%. A project budgeted for 18 months often runs 22–30 months. Budget overruns of 30–50% are common.

Odoo Implementation: Fast, Iterative, Low-Risk

Odoo implementations for manufacturing typically follow an “MVP-first” approach:

Week 1–2: Discovery & Planning

- Map current processes (not idealized processes)

- Identify “must-have” modules for launch (usually 3–5)

- Data extraction from legacy systems

Week 3–4: Configuration & Customization

- Activate core modules (Inventory, Manufacturing, Accounting)

- Configure workflows to your actual processes

- Build 1–2 custom modules if needed

- Comprehensive training for power users

Week 5–6: Testing & Go-Live

- Full system testing in production-like environment

- Parallel running (optional, for risk mitigation)

- Go-live with high confidence

- Post-launch optimization (continuous)

Total Timeline: 4–6 weeks to MVP. Additional modules (CRM, eCommerce, HR) launch in phases over subsequent months.

The Business Impact of Speed

SAP’s 18-month delay costs manufacturers:

- Lost production optimization opportunities (18 months of inefficiency)

- Delayed supply chain visibility (competitive disadvantage)

- Market changes that obsolete your original ERP strategy mid-project

- Team burnout from multi-year implementation disruption

Odoo’s 4–6 week timeline creates:

- Immediate inventory visibility and optimization

- Fast time-to-value (ROI realization starts in Month 3–4)

- Flexibility to incorporate mid-implementation learnings

- Rapid end-user adoption (training fresh, motivation high)

One US steel manufacturer we worked with reported achieving 30% faster order-to-fulfillment cycles within 8 weeks of Odoo go-live, a competitive advantage that would have taken 18+ months to even plan with SAP.

Flexibility & Customization: Monolithic vs. Modular Architecture

‘s monolithic design, by contrast, treats customization as a last resort—something to be avoided, not enabled.

This is where the philosophy gap becomes most evident.

SAP’s Monolithic Approach: “Fit Your Business to the System”

SAP was designed with a fundamental premise: “Our way is the right way. If you follow our best practices, you’ll succeed.”

This creates a constraint: You must change your business to fit SAP, not the other way around.

Want to track labor costs by machine operator (not just by department)? Custom development required—$100K+.

Need to integrate real-time IoT sensor data from your shop floor? SAP’s architecture wasn’t designed for this. You’ll need a middleware layer and custom code—$200K–$500K project.

Require different approval workflows for different plants? Not natively supported. Configuration nightmare.

By the time you’ve bent SAP to fit your actual business, you’ve spent millions on customization—and created a technical debt monster that your internal team can’t maintain.

Odoo’s Modular, Composable Approach: “Build Your System to Fit Your Business”

Odoo’s foundation is fundamentally different. It’s designed as a collection of independent apps that communicate via APIs.

Result:

- Start with core modules (Manufacturing, Inventory, Accounting)

- Add CRM, Quality, Maintenance as you need them

- Build custom modules for unique requirements (without licensing fees)

- Modify workflows to match your actual processes, not SAP’s prescribed ones

- Integrate IoT, eCommerce, and external systems via APIs

Example: A precision metals fabricator needed:

- Multi-level bills of material (MRP-level complexity)

- Real-time OEE tracking from shop-floor sensors

- Custom labor cost allocation by machine and operator

- Integration with legacy CAD/CAM system

- Subcontracting workflow with external supplier portals

With Odoo:

- Core MRP module: 1 day configuration

- IoT sensor integration: 2-week custom module build (vs. $200K+ with SAP)

- Labor cost automation: 3-day configuration + 1-week custom module

- Legacy system integration: 2-week API build (vs. $500K+ with SAP)

- Supplier portal: Built from existing Odoo portal templates, 1-week customization

Total additional cost: $50K–$80K

Total timeline: 6 weeks

With SAP: Would be $500K–$1M and 6+ months

The Open-Source Advantage

Odoo is open-source. This means:

- You own the code

- You’re not locked into Odoo’s vendor roadmap

- Your developers can modify anything

- You don’t pay licensing fees for each custom module

For manufacturing, this flexibility is invaluable. Your competitive advantage often comes from unique operational capabilities. Odoo doesn’t make you choose between competitive advantage and cost.

Real Costs in Action: Manufacturing Case Studies

Case Study 1: Indian Steel Manufacturer – Order Processing Transformation

Company Profile:

- 350 employees, $45M annual revenue

- Producing specialty steel alloys for automotive, aerospace, construction

- Previously on SAP ECC, struggling with manual quotation processes

The Problem:

- Average quote turnaround: 3–5 days

- 60% of quotes required revisions due to specification miscommunication

- Lost 20–25% of competitive bids due to slow turnaround

- Production team had zero real-time visibility into quote-to-order status

Odoo Implementation (6 weeks):

- Deployed Manufacturing MRP, Quality, Inventory modules

- Built custom quote template system linking specifications to BOM and production capacity

- Integrated real-time production schedule visibility with quote engine

- Automated revision tracking and stakeholder notifications

Results (First 6 Months):

Metric Before After Improvement Quote Turnaround 3–5 days 1–2 days 60–75% faster Quote Revision Rate 60% 12% 80% reduction Order Fulfillment Speed 45 days avg. 32 days avg. 30% faster Win Rate on Competitive Bids 75–78% 88–91% +13–18% Production On-Time Delivery 82% 94% +12%

Financial Impact:

- Increased revenue from faster order processing: +₹8.5M annually

- Reduced expediting/overtime costs: +₹2.3M savings

- Improved customer satisfaction (NPS increase): 58→78

- Implementation cost: ₹35L (vs. ₹2–3Cr for SAP)

- Payback period: 2 months

Case Study 2: Bangladesh Food Manufacturer – Cost Reduction Through Labor Transparency

Company Profile:

- 520 employees, $28M annual revenue

- Producing packaged food products (biscuits, confectionery) for local and export markets

- Running on legacy ERP with manual spreadsheet-based labor costing

The Problem:

- Labor costs were estimated, not actual (weekly reconciliation nightmare)

- Production waste was tracked informally—no systematic optimization

- No real-time production reporting (48+ hour delay)

- Multiple facilities operating with inconsistent processes

- Compliance reporting for government audits was manual and error-prone

Odoo Implementation (5 weeks, including 2 facilities):

- Manufacturing MRP module with multi-facility support

- Real-time labor tracking (operator ID at each work center)

- Waste tracking and batch-level cost allocation

- Automated compliance reporting (Bengali language support, local format)

- Shop floor terminals for real-time production data entry

Results (First 12 Months):

Metric Before After Improvement Production Cost Visibility Estimated 100% Actual Perfect accuracy Weekly Reconciliation Work 16 hours 4 hours 75% time reduction Waste Identification Time Manual, slow Real-time Immediate action Production Cost per Unit Baseline -10.2% Cost reduction Compliance Audit Time 40 hours 8 hours 80% reduction Production Reporting Lag 48 hours Real-time 100% improvement

Financial Impact:

- Identified production inefficiencies: ₹62L annual savings

- Reduced administrative labor: ₹28L/year

- Avoided compliance fines (accurate reporting): ₹0 (previously ₹5–8L/year)

- Improved customer relationships (on-time delivery): +₹18L revenue

- Implementation cost: ₹25L (vs. ₹1.5–2Cr for SAP migration)

- Payback period: 3.2 months

Case Study 3: ASEAN Precision Components Manufacturer – Inventory Transformation

Company Profile:

- 280 employees, $22M annual revenue

- Producing precision-engineered components for industrial machinery

- SAP ECC system with recurring inventory accuracy issues

The Problem:

- Inventory accuracy: 72% (expected: 95%+)

- Monthly stock counts revealed ₹35–45L in unreconciled differences

- Production delays due to incorrect inventory information

- Excess safety stock maintained to compensate for unreliability

- Manual cycle counting across 12 SKU categories

Odoo Implementation (4 weeks):

- Inventory module with barcode scanning across receiving, storage, production, shipping

- Real-time stock visibility by location, serial number, and batch

- Automated reorder point and safety stock calculations

- Integration with quality module for defect tracking and scrap management

Results (First 9 Months):

Metric Before After Improvement Inventory Accuracy 72% 97.3% +25.3% Monthly Reconciliation Variance ₹35–45L ₹2–3L 93% reduction Production Schedule Delays (Inventory) 15–18%/month 2–3%/month 85% reduction Excess Safety Stock ₹1.8Cr ₹1.2Cr ₹60L released Stock Count Effort 120 hours/month 8 hours/month 93% reduction Purchase Order Accuracy 88% 99.2% +11.2%

Financial Impact:

- Working capital released (reduced excess inventory): ₹60L (immediate cash benefit)

- Reduced carrying costs: ₹14L/year

- Eliminated production delays (improved on-time delivery): +₹22L revenue

- Reduced shrinkage/theft: ₹8L/year

- Implementation cost: ₹18L

- Payback period: 1.8 months + ₹60L cash release

2026 Game-Changer: Odoo 20 & Agentic AI

Manufacturing ERP is entering a new era. Odoo 20 (releasing September 2026) introduces capabilities that fundamentally change how operations run.

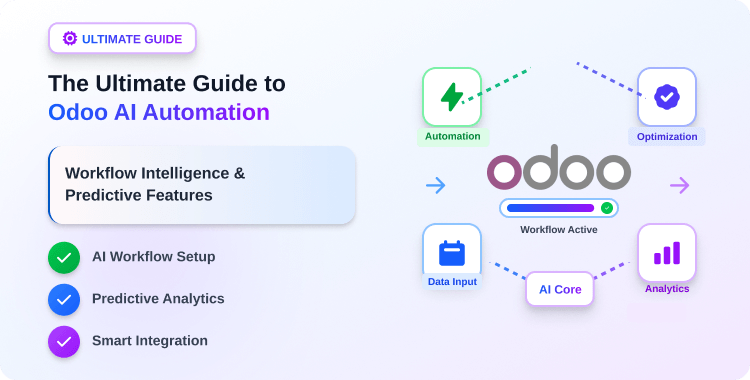

What Is “Agentic AI” in Odoo 20?

Traditional AI/Copilots: You ask the system for information. “Show me inventory status” or “What’s my demand forecast?” The system responds, and you make decisions.

Agentic AI: The system makes decisions and takes actions autonomously, with human oversight.

Examples:

- Production Rerouting: When a machine breaks down, Agentic AI automatically reroutes production to alternate work centers, updates the schedule, notifies affected teams, and escalates if outside policy parameters

- Procurement Automation: When inventory drops below reorder point, the system automatically creates purchase orders, selects suppliers based on cost/lead time/reliability, updates the master schedule, and notifies procurement

- Predictive Maintenance: IoT sensors detect equipment degradation. Agentic AI schedules preventive maintenance during low-utilization windows, orders required parts, arranges technicians, and minimizes production impact

- Quality Management: When defect patterns emerge, Agentic AI identifies root causes, adjusts process parameters, notifies quality team, updates supplier scorecards, and implements corrective actions

Why This Matters for Manufacturing

Odoo 20 Roadmap (Confirmed for September 2026 release):

- Agentic AI for production rerouting and dynamic scheduling

- Predictive maintenance with IoT integration

- Real-time demand sensing and automatic reforecasting

- Autonomous invoice matching and payment processing

- Intelligent supply chain exception handling

- Autonomous quality control and defect prevention

SAP’s Status (January 2026):

- SAP’s “Joule” AI is still copilot-based (asks vs. acts)

- Autonomous operations capabilities are “roadmap” (2027–2028 timeline)

- Requires additional expensive modules and consulting

For manufacturers competing in 2026–2027, Agentic AI isn’t a nice-to-have. It’s a necessity. Companies with agentic operations will operate faster, cheaper, and more reliably than those still using human-dependent processes.

Odoo is shipping this in September 2026. SAP is still planning it.

Common Pitfalls & How to Avoid Them

Pitfall 1: “Let’s Replicate Our Old SAP Setup in Odoo”

Why This Fails: You’ve spent 18 years optimizing processes to fit SAP’s constraints. Don’t repeat those constraints.

The Right Approach:

- Use the transition to rethink processes. What would you do differently if starting fresh?

- Leverage Odoo’s flexibility to remove old workarounds and complicated configurations

- Example: If SAP forced you to use 15 cost centers because of hierarchical limitations, Odoo’s flexible accounting structure might reduce this to 4–6

- Outcome: Simpler system, faster processes, lower TCO

Pitfall 2: “Underestimating Change Management on a 4-Week Timeline”

Why This Fails: Just because implementation is fast doesn’t mean change management is optional.

The Right Approach:

- Involve production supervisors, inventory managers, and accountants from Week 1

- Run parallel operations for 1–2 weeks post-go-live (not 6 months, but essential for confidence)

- Build a “super-user” group trained by week 3, enabling train-the-trainer capacity

- Plan for post-go-live support (24 hours/day for first 2 weeks)

- Outcome: Fast adoption, minimal disruption, high confidence

Pitfall 3: “Over-Customizing on Day One”

Why This Fails: Odoo’s flexibility is seductive. Teams sometimes build custom modules for every edge case, creating maintenance debt.

The Right Approach:

- Rule of 80/20: Solve 80% of needs with native Odoo functionality and configuration

- Defer edge cases: That 20% can be custom modules, but build them only after seeing real usage patterns

- Iterate: Customize based on actual pain points, not theoretical scenarios

- Outcome: Lower cost, easier maintenance, faster to value

Pitfall 4: “Ignoring Integration Complexity”

Why This Fails: Manufacturing involves multiple systems (MES, IoT, CAD/CAM, eCommerce, accounting, HR). Odoo doesn’t replace all of them—it integrates with them.

The Right Approach:

- Map data flows (what comes into Odoo, what goes out) before implementation starts

- Identify 2–3 critical integrations for Day 1 go-live

- Plan additional integrations as phases (Month 2–3, then Month 4–6)

- Use Odoo’s REST API and middleware platforms (Zapier, Integromat) for complex flows

- Outcome: Phased integration complexity, lower risk, staged learning

Advanced Strategy: The “Phased Module Rollout” for Large Operations

For manufacturers with multiple facilities or complex requirements:

Phase 1 (Week 1–6): Core Manufacturing

- Go-live with Inventory + Manufacturing + Accounting

- Target: One production facility or one product line

- Success criteria: 95%+ inventory accuracy, zero production delays from system

Phase 2 (Week 7–14): Quality & Supply Chain

- Add Quality module, integrate supplier portals

- Expand to second facility

- Success criteria: Real-time defect tracking, automated supplier communication

Phase 3 (Week 15–24): Advanced Analytics & CRM

- Add advanced forecasting, CRM, eCommerce

- Full company integration

- Success criteria: Real-time dashboards, improved sales-to-cash cycle

Result: You’re live in 6 weeks with core capability, then continuously improving over 6 months—vs. SAP’s 18-month all-or-nothing implementation.

Advanced Strategies: Maximizing Odoo’s Flexibility & ROI

Strategy 1: Smart Subcontracting & Partner Networks

Odoo’s portal functionality is built for this. Create real-time visibility into subcontractor performance:

- Subcontractors receive work orders automatically

- Track quality metrics and delivery performance continuously

- Automate payment based on quantity-received + quality score

- Outcome: Better partner relationships, fewer disputes, improved supply chain resilience

Strategy 2: Real-Time Production Analytics for Continuous Improvement

Don’t just collect data—act on it:

- Daily production dashboards showing OEE, scrap, delays by work center

- Weekly kaizen meetings informed by actual system data (not spreadsheets)

- Automated alerts for anomalies (e.g., reject rate spike, cycle time increase)

- Outcome: Continuous 1–2% monthly productivity improvements compound to 15–20% annual gains

Strategy 3: Leverage IoT Data for Predictive Maintenance

Connect your shop floor:

- IoT sensors on critical equipment send vibration, temperature, pressure data to Odoo

- Machine learning algorithms detect degradation patterns

- Odoo automatically schedules preventive maintenance during low-utilization windows

- Outcome: Reduce unplanned downtime by 60–80%, extend equipment life by 15–25%

Strategy 4: Build Your Own Competitive Moat Through Custom Modules

Open-source means you can:

- Develop proprietary algorithms for demand forecasting

- Build custom workflows that embody your operational excellence

- Create APIs that lock in your customer/supplier ecosystems

- Outcome: Continuous innovation without vendor dependency

The 2027 SAP Deadline: Why It’s a Catalyst

SAP ECC support ends December 31, 2027. Customers must migrate to S/4HANA.

The Math:

- S/4HANA migration: $500K–$2M + 12–24 months

- Odoo switch: $130K–$260K + 4–6 weeks

- Difference: $2–4M + 18–20 months

For many manufacturers, the 2027 deadline is the forcing function to ask: “Do we really need S/4HANA? Or is this the right time to evaluate alternatives?”

The answer, increasingly, is Odoo.

Frequently Asked Questions

1. Is Odoo Enterprise-Grade? Can It Handle Our Complexity?

Yes, absolutely. Odoo powers over 15,000 manufacturing companies worldwide, including Toyota, Del Monte, and Sodexo. The platform handles discrete manufacturing (custom products), process manufacturing (bulk/continuous), and hybrid models with equal sophistication.

Odoo is best suited for manufacturers with $10M–$500M in annual revenue who need flexibility and don’t require the legacy enterprise features that massive Fortune 500 ERP deployments demand. For companies in this range—the overwhelming majority of manufacturers—Odoo delivers enterprise-grade capability without enterprise-grade complexity, cost, and rigidity.

HasTech IT Ltd has successfully implemented Odoo across diverse manufacturing verticals in Bangladesh and South Asia, from garment production to food manufacturing to metal fabrication, consistently delivering measurable results within compressed timelines.

2. What’s the Real Risk of Switching Away from SAP?

The risk is lower than you think, if you execute properly. The biggest perceived risk is abandoning a “known” system. But SAP’s complexity creates significant risk too: vendor lock-in, expensive customizations that don’t translate to competitive advantage, and multi-year implementation cycles where market conditions change before the project completes.

Odoo’s risks are different and more manageable:

You’re switching to a vendor with a smaller ecosystem (though the community is massive, 7M+ users)

You lose SAP’s “brand authority” with some traditional enterprise customers

Real implementation risk: choosing an inexperienced or inadequately qualified Odoo partner

Mitigation strategy: Partner with a certified, experienced Odoo implementation provider like HasTech IT Ltd with proven manufacturing expertise. Invest in proper data migration, comprehensive testing, and structured user training. Plan for 4–8 weeks of intensive collaborative work, not 18 months of dependency on consulting.

3. How Does Odoo Compare to Microsoft Dynamics 365 or Oracle NetSuite?

Cost: Odoo typically costs 40–60% less than Dynamics 365 or NetSuite over a 5-year horizon.

Flexibility: Odoo’s open-source foundation and modular architecture provide superior customization capability compared to Dynamics or NetSuite, which still favor standardization over adaptation.

Manufacturing Features: For discrete manufacturing, all three are technically capable. Odoo’s edge is in speed to value and cost efficiency. Microsoft Dynamics 365 offers advantages if you’re deeply committed to the Microsoft ecosystem (Office 365, Power BI integration). Oracle NetSuite excels in multi-subsidiary accounting for large global enterprises.

Bottom line for manufacturers: If you’re a mid-market operation looking for fast implementation and lower TCO, Odoo wins decisively. If you’re a Fortune 500 multinational already embedded in Microsoft or Oracle ecosystems with complex transfer pricing requirements, the switching costs might not justify migration to Odoo.

4. What About Ongoing Support & Updates After Going Live?

Odoo’s support model is fundamentally different—and superior for agility. With SAP, you pay annual maintenance (typically 17–20% of your license cost annually) and schedule major upgrades like projects, often requiring downtime and re-testing.

With Odoo, you subscribe to an Enterprise edition or hire a support partner like HasTech IT Ltd. Updates happen continuously (monthly releases), are backward-compatible, and don’t require downtime. There’s no forced upgrade cycle—you can stay on your current version indefinitely and upgrade when it makes business sense for your organization.

HasTech provides dedicated post-implementation support, including:

1. Proactive system monitoring and optimization

2. User training and knowledge transfer

3. Ongoing customization and module development

4. Integration support with local Bangladesh systems (NBR compliance, payment gateways, etc.)

5. Performance optimization and scalability support

5. How Long Does It Take to See ROI After Switching to Odoo?

Short answer: 12–18 months, often much sooner. Manufacturing case studies show:

Immediate benefits (Month 1–3): Reduced manual data entry, faster order processing, real-time inventory visibility, improved production planning

Medium-term gains (Month 4–8): Process optimization, labor cost reduction, waste elimination, improved quality metrics

Full ROI (Month 12–18): Cumulative savings from automation, improved forecasting, and operational efficiency typically exceed the total implementation and first-year subscription costs

Compare this to SAP, where ROI often arrives in Year 3 after a 2-year implementation—if at all.

For Bangladesh-based manufacturers specifically, HasTech has documented cases where clients achieved payback within 8–12 months through reduced manual reconciliation work, improved inventory accuracy, and streamlined compliance processes (VAT automation, NBR reporting).

Ready to Transform Your Manufacturing Operations? Partner with HasTech IT Ltd

The case for Odoo is clear: dramatically lower cost, faster deployment, superior flexibility, and agility for manufacturing environments that demand innovation. But success depends on expert implementation from a partner who understands your business, your market, and your manufacturing challenges.

HasTech IT Ltd stands out as your trusted Odoo implementation partner in Bangladesh and South Asia. Founded in 2015, HasTech brings proven expertise across diverse manufacturing sectors with a track record of fast-track implementations, deep manufacturing domain knowledge, and ongoing partnership commitment.

Why partner with HasTech IT Ltd:

- Manufacturing Expertise: Deep understanding of production workflows, supply chain challenges, discrete/process manufacturing models, and quality management requirements

- Certified Odoo Partner: Proven capability and commitment to Odoo best practices and customer success

- Fast-Track Implementation: Proven methodologies delivering go-live in 4–8 weeks, not months

- Local Bangladesh Presence: Based in Dhaka with regional support, ensuring accessibility for companies across South Asia

- Domain Knowledge: Expert understanding of Bangladesh-specific requirements including NBR compliance, VAT automation, local payment gateway integration, and regional business practices

- Post-Implementation Partnership: Ongoing optimization, training, scaling, and continuous improvement support

Ready to explore your Odoo transformation?

We’ll assess your current ERP challenges, map your path to Odoo, and show you exactly how you can cut costs while accelerating operational efficiency—tailored to your manufacturing model and Bangladesh market context.

No sales pitch. No pressure. Just a straightforward conversation about whether Odoo is the right move for your manufacturing operation, and how HasTech can guide you through a successful transformation.

Conclusion: The Shift Is Real And It’s Accelerating

The age of one-size-fits-all enterprise ERPs is ending. Manufacturing companies that thrived with SAP in the 1990s and 2000s are discovering that the system’s complexity, cost, and rigidity no longer align with 2026 realities: volatile supply chains, accelerating digital transformation, labor shortages, and the need for continuous innovation.

Odoo isn’t a replacement in the traditional sense. It’s a different philosophy: modular over monolithic, flexible over standardized, fast over methodical, transparent over proprietary.

The numbers support the shift:

- 5–10 times lower TCO over a 5–7 year horizon

- 4–6 week implementations vs. 12–24 month SAP projects

- 30% faster order processing, 10–30% production cost reductions, and 90% inventory accuracy improvements documented in real case studies

- 92% of manufacturing leaders already recognize that agility and modern ERP architecture are strategic imperatives

The question isn’t whether you should evaluate Odoo, it’s whether you can afford not to, especially as the SAP ECC 2027 support deadline forces a decision anyway.

When faced with a multi-million-dollar S/4HANA migration or a low-cost, fast Odoo implementation, manufacturers increasingly choose agility, cost efficiency, and operational independence.

Ready to explore your Odoo opportunity? Partner with HasTech IT Ltd, where manufacturing expertise meets Odoo excellence. Start a discovery conversation today; your transformation might be just 4–6 weeks away.