Streamline Production with the Odoo Manufacturing MRP Module: The Complete Guide

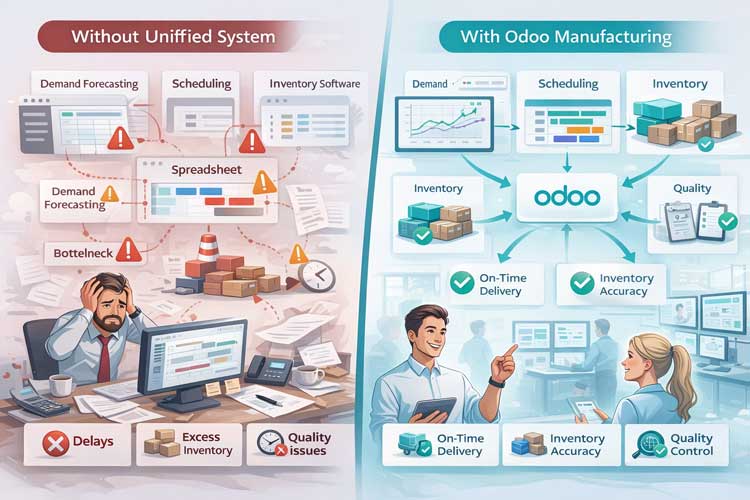

Manufacturing inefficiency costs U.S. manufacturers an estimated $15.7 billion annually in lost productivity and excess inventory. For production managers working with disconnected systems, this reality is painful.

When your production planning system can’t communicate with your inventory system, and neither speaks to your quality control process, inefficiency becomes inevitable. Work orders get delayed waiting for materials. Machines sit idle due to poor scheduling. Quality issues discovered too late trigger costly rework.

Yet a growing number of manufacturers are leveraging integrated ERP solutions—specifically Odoo’s Manufacturing MRP module- to consolidate operations, automate scheduling, and cut production lead times by up to 40%.

The challenge is no longer about having access to technology, it’s about integrating disparate systems into a unified, intelligent platform that responds to real-time changes.

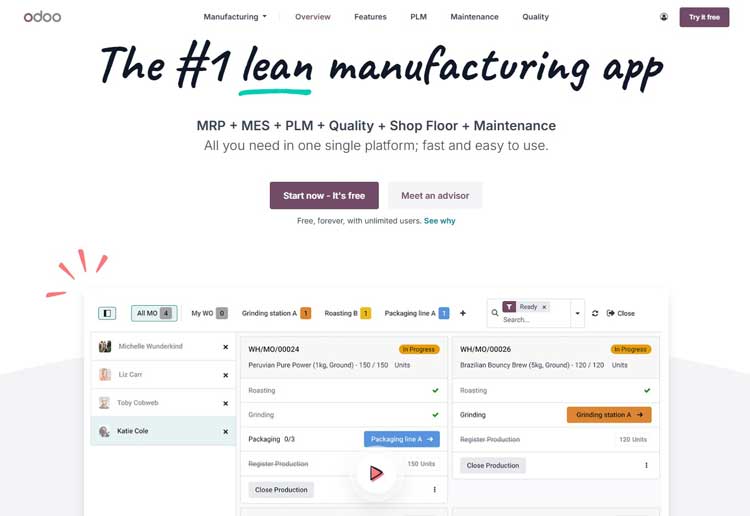

Whether you’re a small job shop managing a handful of products or a mid-market assembly operation with hundreds of SKUs, this comprehensive guide explores how Odoo Manufacturing streamlines every stage of production and why it’s becoming the go-to solution for manufacturers seeking unified control.

Key Takeaways

- Reduce production lead times by 40% with intelligent scheduling

- Real-time inventory tracking prevents costly stockouts automatically

- One platform integrates planning, execution, and quality control

- AI-powered demand forecasting aligns output with actual demand

- Multi-level BOM management handles complex manufacturing

- 25-40% lead time reduction, 20-30% inventory cost savings

ShopLentor- WooCommerce Builder for Elementor & Gutenberg

A versatile page builder to build modern and excellent online stores with more than 100k+ Active Installations.

How Odoo Manufacturing MRP Works

Material Requirements Planning (MRP) is the methodology that calculates what materials you need, when you need them, and in what quantities based on your production schedule and current inventory levels.

Unlike simpler inventory systems, MRP looks upstream to demand forecasting and downstream to shop floor execution, creating a complete planning ecosystem. Odoo automates this process, eliminating manual spreadsheets and disconnected platforms.

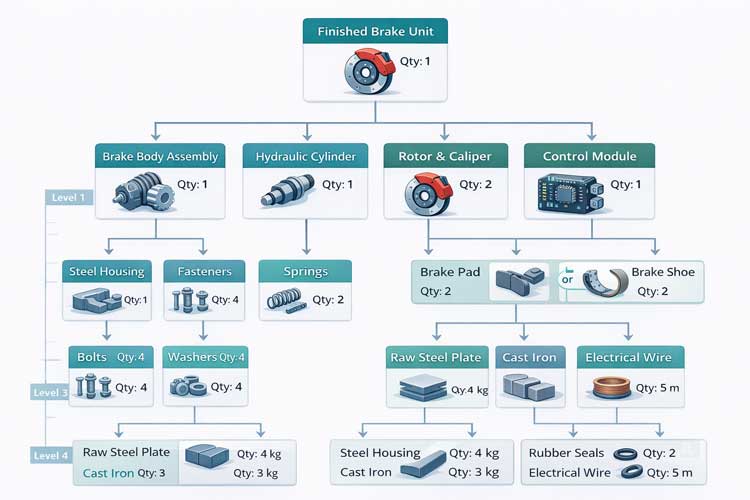

1. Bill of Materials (BOM) Management

The Bill of Materials is the foundation of all production planning, it’s the recipe that tells the system what components and materials are required to build each product, in what quantities, and in what sequence.

Key capabilities:

- Multi-level BOMs: Create hierarchical BOMs where subassemblies roll up into finished products. Example: An automotive brake assembly might have 5 levels, finished brake unit → brake body assembly → stamped housing → fasteners → raw materials. Each level can have its own manufacturing routing and work instructions.

- Alternative components: Specify which components can substitute for others when preferred materials are out of stock, enabling flexibility without compromising quality.

- Shared BOMs across product families: Use template BOMs that multiple products reference. Change the template once, and updates cascade to all products automatically.

- Real-world impact: An electronics manufacturer with 50 different circuit boards shares 70% common components using a shared BOM template. They changed a common capacitor specification once and automatically updated sourcing for all 50 products.

How accurate BOMs prevent delays: Inaccurate BOMs are responsible for 15-20% of production delays. When the system builds a work order based on incorrect material specifications, you discover the problem mid-production when wrong parts arrive.

Odoo prevents this through BOM versioning that tracks all historical versions with effective dates, ensuring production orders use the correct BOM version.

2. AI-Powered Demand Forecasting

Traditional manufacturing relies on static forecasts created quarterly. This disconnect causes either overproduction (excess inventory) or underproduction (stockouts and lost sales). Odoo’s demand forecasting continuously learns from actual market signals.

How it works:

- Analyzes historical sales data from the past 12-36 months

- Identifies seasonal trends (e.g., lawn equipment sales spike in spring)

- Incorporates market signals from actual customer orders and sales pipeline

- Adjusts for anomalies (one-time large orders don’t skew the forecast)

- Automatically updates as new sales data arrives

Automatic work order generation: You set forecast thresholds for each product (e.g., “generate a work order when forecasted 30-day demand exceeds 80% of available inventory”). When conditions are met, Odoo automatically creates production orders and purchase orders—no manual intervention needed.

Financial impact: Manufacturers implementing automated demand forecasting typically reduce inventory carrying costs by 20-30% while simultaneously reducing stockouts.

Consider a $50M manufacturing company with typical inventory representing 15% of revenue ($7.5M in inventory carrying costs). A 25% reduction through better forecasting equals $1.875M in freed working capital, capital currently tied up unnecessarily.

Real example: A custom furniture manufacturer was chronically overproducing leather sofas based on quarterly forecasts.

By implementing Odoo’s continuous forecasting, they reduced sofa inventory by 35% (from 45-day to 30-day supply), increased on-time delivery from 82% to 94%, and freed up $400K in working capital plus warehouse space.

3. Finite Capacity Scheduling (Gantt Charts)

Here’s the hard truth: you can have perfect forecasts and flawless BOMs, but without finite capacity planning, you’ll still miss deadlines. Finite capacity scheduling means scheduling work orders based on actual available capacity—not assuming unlimited machine time.

Visual scheduling advantages:

- Gantt charts show production schedules as timeline visualizations, with each work order as a colored bar

- Drag-and-drop interface lets you reschedule jobs by dragging from one machine to another or from one time period to another.

- System instantly recalculates dates and checks for new conflicts when you make changes.

- Visual display immediately shows overlapping bars that indicate schedule conflicts.

Identifying bottlenecks before they stall production: A bottleneck is a work center that can’t handle the workload—it becomes the constraint limiting total output. Classic example: you have three machining centers and an inspection station.

If all three machines are running at capacity but inspection can only handle output from two machines, inspection becomes your bottleneck. Production builds up in the queue before inspection, and jobs miss their delivery dates.

Odoo’s capacity planning identifies this scenario during scheduling, not during production when it’s too late. The system calculates cumulative workload for each resource, alerts when a resource exceeds 100% capacity, suggests alternative work centers or extended timelines, and enables “what-if” scenario planning.

Real-world impact: A job shop manufacturer with five CNC machines was scheduling everything on machine #1 because the operator was most experienced. Other machines ran at 40-60% utilization.

After implementing Odoo’s capacity-aware scheduling, work was distributed across machines based on availability and capability, overall throughput increased 28% (no new equipment added), lead times dropped from 21 days to 15 days, and operator utilization equalized.

4. Real-Time Inventory Control and Prevention of Stockouts

Accurate inventory tracking is the foundation of reliable production planning. If you don’t know what materials you have on hand, your production schedule is fiction.

Real-time tracking across multiple warehouses:

- Main warehouse, satellite warehouses, and quarantine areas (for materials under quality hold)

- Customer-owned materials (consignment inventory you manufacture)

- Work-in-process (materials currently in production)

- Finished goods staged for shipment

Every movement—receiving materials, moving to production, consuming in work orders, shipping to customers—updates inventory in real-time.

Automatic replenishment: In Odoo 18, the MRP module includes automatic replenishment triggered by minimum stock thresholds. You set minimum stock levels for each material (e.g., “never let raw steel tube inventory fall below 500 units”).

When inventory drops below the threshold, Odoo automatically generates a purchase order timed so materials arrive just-in-time for planned production.

Serial and lot number tracking: Manufacturing requires traceability—the ability to track which materials went into which finished product and which customer received that product.

This is critical for product recalls, quality investigations, and regulatory compliance. Odoo captures serial numbers and lot numbers at the point of material receipt and tracks them through production.

Barcode integration for accuracy: Manual inventory counts are error-prone. Barcode scanning reduces errors from an average of 1 per 300 keystrokes (manual entry) to near-zero.

Odoo integrates with standard barcode scanners (USB, Bluetooth, mobile apps) to automatically scan materials as they arrive, scan work orders as production starts, and scan finished goods for quality inspection and shipment.

5. Automated Procurement and Vendor Management

Production delays often originate in procurement, not manufacturing. Materials arrive late, wrong parts are ordered, or suppliers provide poor-quality components.

Auto-triggered purchase orders: Rather than manually creating purchase orders, Odoo’s MRP engine automatically generates them. Production schedule requires 1,000 units of component X. MRP checks current inventory and committed purchase orders.

If insufficient stock, MRP calculates the purchase quantity and timing to ensure material arrives before needed, then generates the purchase order automatically.

Vendor performance tracking: Odoo tracks vendor metrics that impact your ability to deliver on time: on-time delivery rate, quality rate, lead time consistency, and cost competitiveness. The system scores vendors on these metrics, enabling intelligent vendor selection.

Real-world impact: A machinery manufacturer with $15M annual procurement spend reduced procurement lead time by 15-20 days by automating PO generation. Materials arrived earlier, reducing the need for safety stock.

Rush shipments decreased from 30% to 5% of orders (saving overnight shipping costs). Better cash flow resulted from purchasing just-in-time rather than speculative bulk buys.

6. Production Cost Analysis and KPI Monitoring

Manufacturing profitability depends on understanding true production costs. Yet most manufacturers can’t accurately answer: “What did it cost to manufacture product X?”

Cost components captured:

- Material costs (valued at actual receipt price)

- Labor costs (hours consumed across work centers at actual rates)

- Machine/overhead allocation (depreciation, utilities, maintenance allocated based on run time)

- Quality costs (rework, scrap, inspection time)

Planned vs. actual comparison: When you create a work order, Odoo calculates the planned cost based on BOM material prices, planned labor hours and rates, and estimated machine time.

As production proceeds, actual costs are captured from material tracking, employee timesheets, and IoT sensors. At job completion, you have a complete variance report showing where the job ran over or under budget.

Real example: Planned cost: $1,250. Actual cost: $1,380. Variance: $130 over budget (10.4% unfavorable). This immediately flags jobs that are running over budget, allowing corrective action mid-production rather than discovering margin problems weeks later.

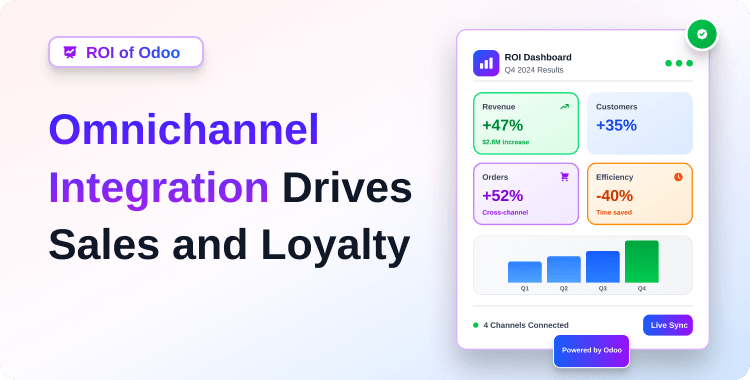

KPI dashboard: Manufacturing leadership sees live dashboards showing overall equipment effectiveness (OEE), first-pass quality rate, on-time delivery rate, inventory turns, and production cycle time, updated hourly or in real-time with IoT sensors, not monthly through accounting reports.

7. Quality Control and Compliance Integration

Manufacturing without quality control is just creating expensive scrap.

In-line quality checkpoints: Rather than inspecting only at the end, Odoo enables quality checkpoints embedded within the production workflow.

After operation #1 (first-pass dimension check before further processing), after operation #3 (before expensive finishing operations), and final inspection before shipment.

At each checkpoint, inspectors scan the work order barcode, perform specified tests or measurements, and record results. The system automatically accepts or rejects the work order.

Quality impact: Quality control integration typically reduces defect rates by 15-20%, reducing scrap and rework. For a manufacturer with 3% defect rate on $50M revenue ($1.5M in scrap), reducing defects to 2.5% saves $500K annually.

Traceability for recalls: Industries like pharmaceuticals, medical devices, and food manufacturing require full traceability.

If a problem is discovered with a batch of materials or finished products, you must identify which finished products contain that material and identify which customers received those products. Odoo’s serial/lot tracking enables precision recalls in minutes rather than days.

8. IoT Integration and Shop Floor Automation

The future of manufacturing (Industry 4.0) connects equipment, systems, and people in real-time.

IoT Box connectivity: The Odoo IoT Box is a small hardware device that connects to your manufacturing equipment—barcode scanners, RFID readers, weight scales, temperature sensors, industrial PLC controllers, and label printers.

The IoT Box bridges legacy equipment (not designed for digital connectivity) to Odoo’s software. Data flows from equipment sensors directly into Odoo.

Real-time equipment monitoring and predictive maintenance: When equipment is connected, Odoo monitors run time and utilization, error codes and anomalies, performance trends, and energy consumption.

This enables predictive maintenance—servicing equipment before it fails, rather than waiting for a breakdown. A machine bearing showing subtle vibration, indicating wear, gets flagged for maintenance before the bearing seizes and causes 8+ hours of downtime.

Impact: Manufacturers with predictive maintenance reduce unplanned downtime by 40%. For a manufacturer with 5 machines running $2K/hour revenue when operating, preventing even one 8-hour breakdown per quarter equals $64K in recovered revenue annually.

Mobile shop floor control: Supervisors and operators use tablet-based Odoo interfaces with barcode scanning. No need to walk to an office computer to update production status.

Why Manufacturers Choose Odoo

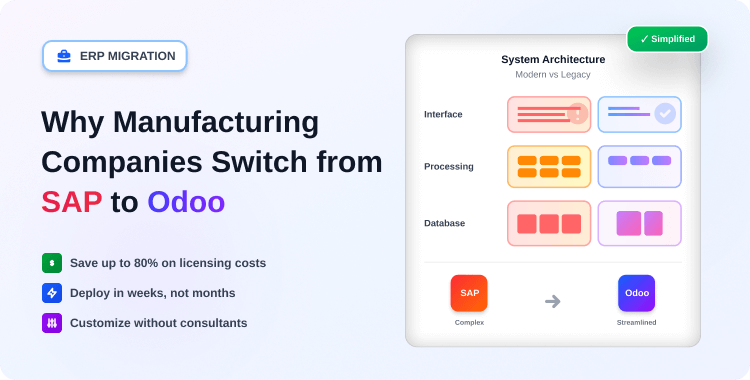

| Factor | Odoo | NetSuite | SAP Business One |

| Cost | $0-2K/month (SME) | $2-5K+/month | $1-3K+/month |

| Implementation | 2-8 weeks | 3-6 months | 2-4 months |

| Customization | Unlimited (open-source) | Limited | Complex |

| Manufacturing Focus | Native module | Standard features | Standard features |

| MRP Forecasting | AI-powered | Advanced | Advanced |

| IoT Integration | Native | Add-on | Add-on |

Odoo’s unique advantage: Best balance of cost, flexibility, and built-in manufacturing features for SME/mid-market manufacturers.

Common Implementation Challenges and How Odoo Prevents Them

1. Inaccurate BOMs Causing Production Delays

- Problem: BOMs don’t match what actually gets built, discovered mid-production.

- Odoo solution: BOM versioning, change control workflow, quality integration flags mismatches.

2. Poor Demand Forecasting

- Problem: Forecast is wildly inaccurate, causing over/underproduction.

- Odoo solution: AI forecasting analyzes actual historical data, auto-detects seasonality, and flags anomalies.

3. Siloed Data Preventing Real-Time Decisions

- Problem: Updates in one system take days/weeks to propagate to others.

- Odoo solution: Single unified database shared across all modules, real-time updates.

4. Inadequate Capacity Planning

- Problem: Schedule work but don’t verify actual capacity, causing mid-month delays.

- Odoo solution: Finite capacity scheduling, visual Gantt charts, automatic bottleneck identification.

5. Manual Inventory Tracking Errors

- Problem: Thought you had material, physical count shows you’re short, production halts

- Odoo solution: Barcode scanning is automatic and accurate, with real-time visibility and auto-replenishment

6. Lack of Product Traceability

- Problem: Customer reports a defect, can’t trace which materials went into their unit

- Odoo solution: Serial/lot tracking automated through barcode scanning, batch recalls in minutes

7. Disconnected Procurement and Production

- Problem: Production plans based on one forecast, purchasing buys based on different assumptions

- Odoo solution: MRP automatically generates POs, and the production schedule includes material availability checks

8. No Cost Visibility

- Problem: The actual costs were 15% higher than the estimate after production ended.

- Odoo solution: Real-time cost tracking captures actual labor, materials, overhead; flags overruns mid-production.

Frequently Asked Questions

Q: What is the primary benefit of implementing Odoo Manufacturing MRP?

A: Consolidating production planning, scheduling, inventory, and quality control into one system eliminates costly delays from disconnected platforms and enables 25-40% lead time reduction through automated scheduling and AI-powered demand forecasting.

Q: How long does implementation typically take?

A: 2-8 weeks for SMEs, 2-4 months for mid-market manufacturers. Fast implementation is possible because Odoo uses pre-configured workflows—you’re not building from scratch like legacy ERP systems.

Q: Can Odoo Manufacturing integrate with existing equipment?

A: Yes. The Odoo IoT Box connects barcode scanners, sensors, PLCs, and industrial equipment. Legacy equipment doesn’t require replacement—the IoT Box bridges the connectivity gap cost-effectively.

Q: How much inventory reduction is typical?

A: Manufacturers typically reduce inventory 20-30% through better demand forecasting and automatic replenishment. For a $50M company with 15% inventory value, that’s $1.875M in freed working capital.

Q: Does implementation require supplier participation?

A: No. Odoo works with traditional suppliers using manual POs. However, suppliers sharing forecast data electronically enable just-in-time procurement, maximizing inventory reduction benefits.

About HasTech IT Limited – Your Odoo Manufacturing Partner

HasTech IT Limited is an official Odoo-certified partner specializing in Manufacturing ERP implementations. Based in Bangladesh, we help manufacturers streamline production, optimize supply chains, and build operational resilience through Odoo’s integrated platform.

Why Partner With HasTech:

- Manufacturing-Specific Expertise: We understand job shops, contract manufacturers, and discrete assembly operations—not just software installation. Our consultants work with manufacturers across industries to translate operational requirements into Odoo configurations that drive real business results.

- Fast Implementation: Typical 2-8 week rollout with comprehensive training. We structure implementations to achieve quick wins early—getting your first production orders into Odoo and seeing immediate inventory accuracy improvements.

- Proven Results: Clients achieve 25-40% lead time reduction, 20-30% inventory reduction, and improved on-time delivery within 12 months. Our implementations have tangible, measurable ROI.

- Local Support: Bangladesh-based for responsive timezone support and understanding of regional manufacturing landscape. We can customize Odoo to match your specific operational needs and market context.

- End-to-End Service: Assessment (understand your current processes and pain points) → Configuration (build Odoo to match your workflows) → Training (comprehensive training for all user levels) → Post-go-live support (ongoing optimization and troubleshooting).

Schedule a consultation with HasTech to discuss your specific manufacturing challenges and create a customized implementation roadmap.

Making the Decision

The global ERP market is growing at 7.1% annually, driven by manufacturers recognizing that digital transformation is essential to remain competitive.

Manufacturers who implement unified production planning today are 2-3 years ahead in operational maturity, that advantage compounds as they use superior data and efficiency to invest in further improvements.

Your choice is whether to lead this transformation or follow it. The manufacturers who acted early are now 2-3 years ahead in operational maturity.

Ready to Streamline Production?

Book a demo with HasTech IT Limited – 30 minutes with manufacturing specialists discussing your specific challenges and implementation approach. No sales pitch, just technical expertise aligned to your business goals.

Download the Free MRP ROI Calculator – Estimate your potential savings: inventory cost reduction (based on your current inventory value), lead time improvement impact (faster cash conversion), labor efficiency gains (automation vs. manual tasks), and quality cost reduction (less rework and scrap).

Explore Manufacturing Case Studies – See how manufacturers in your industry transformed operations.

About Odoo

Odoo is an open-source business management suite serving over 7 million users globally. The Manufacturing module is purpose-built for discrete and job-shop manufacturing, balancing operational complexity with user-friendliness for operators, planners, and management.

Key Terms

- MRP (Material Requirements Planning): A system that calculates what materials you need, when you need them, and in what quantities based on demand forecasts and inventory levels

- BOM (Bill of Materials): Complete list of components, materials, and sub-assemblies required to manufacture a product, including quantities

- Gantt Chart: Timeline visualization showing scheduled work orders across machines and time periods, making capacity conflicts immediately visible

- OEE (Overall Equipment Effectiveness): Performance metric calculated as availability × performance × quality, showing how efficiently equipment is running

- Finite Capacity Scheduling: A production scheduling method that respects actual available equipment capacity, not assuming unlimited production time

- IoT (Internet of Things): Network of connected devices (machines, sensors, scanners, controllers) feeding real-time data into Odoo

- Just-in-Time (JIT): Inventory management approach of ordering/producing materials exactly when needed, minimizing storage and carrying costs

ShopLentor- WooCommerce Builder for Elementor & Gutenberg

A versatile page builder to build modern and excellent online stores with more than 100k+ Active Installations.

Conclusion

Odoo Manufacturing MRP consolidates demand forecasting, inventory management, capacity planning, quality control, and cost analysis into one integrated platform. Manufacturers eliminate inefficiencies, reduce lead times by 25-40%, and make data-driven decisions in real time.

Whether you’re a small job shop or mid-market operation, Odoo provides the flexibility and scalability to grow without the prohibitive costs of legacy ERP systems.

The manufacturers leading their industries today aren’t simply implementing new software, they’re transforming operations from reactive, spreadsheet-driven planning to proactive, AI-enabled optimization.

Your next step is to connect with manufacturing experts who understand your specific challenges.

Reach out to HasTech IT Limited to understand how Odoo Manufacturing can specifically address your production challenges and create a transformation roadmap.