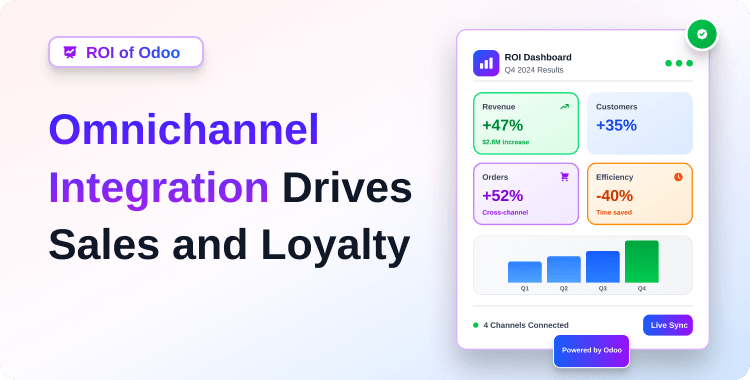

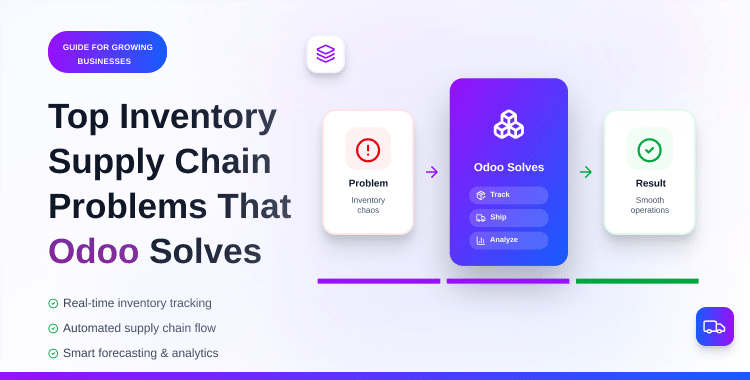

Top Inventory and Supply Chain Problems That Odoo Solves Guide for Growing Businesses

Imagine a scenario that plays out every single day in thousands of businesses worldwide: A customer walks into your store, or logs onto your website, looking for your bestselling product.

Your sales team checks the system and confidently says, “Yes, we have 50 units in stock.” But when your warehouse team goes to pick the order, they find only 12 units actually available.

The rest? This gap between what your software says and what is physically on the shelves is one of the top inventory and supply chain problems that quietly erode profit and customer trust.

Behind that one failed order is a chain of issues: disconnected systems, manual stock updates, poor demand forecasting, and a lack of real‑time visibility across warehouses.

These are not “nice to fix someday” issues; they are exactly the kind of top inventory and supply chain problems that stop companies from scaling.

According to peer‑reviewed research, approximately 65% of inventory records in companies without automated systems contain inaccuracies, leading directly to lost sales and frustrated customers.

Excess inventory alone costs companies between 25–30% of their total inventory value annually through storage, insurance, and obsolescence.

This guide is designed to help you identify and fix the top inventory and supply chain problems using Odoo.

By centralizing stock, purchasing, warehouses, manufacturing, and accounting in one integrated Odoo ERP platform, you can move from reactive firefighting to proactive, data‑driven operations.

In the sections below, you’ll see how Odoo tackles the top inventory and supply chain problems, from stockouts and excess inventory to inefficient purchasing, warehouse bottlenecks, weak forecasting, and complex returns, so your business can grow without losing control of operations.

Key Takeaways

- Use Odoo inventory management to eliminate one of the top inventory and supply chain problems: stockouts caused by inaccurate stock data

- Reduce excess inventory and annual carrying costs by up to 30% through smarter Odoo‑driven planning

- Automate purchase orders and supplier management to remove manual procurement bottlenecks

- Gain end‑to‑end visibility across your supply chain in a single Odoo database

- Streamline warehouse operations with barcode‑driven Odoo inventory workflows

- Cut manual data entry by centralizing processes on one ERP platform

- Scale from a single warehouse to multi‑company, multi‑warehouse operations without changing systems

ShopLentor- WooCommerce Builder for Elementor & Gutenberg

A versatile page builder to build modern and excellent online stores with more than 100k+ Active Installations.

Understanding the Top Inventory and Supply Chain Problems Odoo Can Fix

Before diving into specific problems and solutions, let’s establish what effective inventory and supply chain management actually means for growing businesses.

Inventory management in Odoo is the systematic approach to sourcing, storing, and moving inventory, covering everything from purchase orders and incoming shipments to internal transfers, pickings, and deliveries.

Supply chain management in Odoo goes beyond the warehouse. It coordinates the full flow of goods and information from suppliers through purchasing, manufacturing, MRP, inventory, logistics, and finally to end customers, all inside the same ERP platform.

The most common top inventory and supply chain problems usually appear when businesses lack:

The key foundational components include:

- Real-time visibility: Knowing exactly what you have, where it is, and its current status

- Demand forecasting: Predicting future inventory needs based on historical data and trends

- Automated replenishment: Triggering purchase orders when stock reaches predetermined levels

- Multi-location management: Tracking inventory across warehouses, retail locations, and transit

- Integration capabilities: Connecting inventory data with sales, accounting, and operations systems

When these foundations are missing, you feel the impact as daily operational headaches. When they are correctly implemented in Odoo, those top inventory and supply chain problems become structured, manageable processes instead of constant fire‑fighting.

Top Inventory and Supply Chain Problems Odoo Solves

Problem 1: Inaccurate Inventory Data Leading to Costly Stockouts

The Challenge:

Manual inventory tracking through spreadsheets or outdated systems creates discrepancies between recorded and actual stock levels. Research shows that inventory record inaccuracy averages 63% in companies without automated systems, leading to lost sales and frustrated customers.

How Odoo Solves It:

Odoo’s inventory module provides real-time tracking with automatic updates across all touchpoints. When a sale occurs, inventory adjusts instantly. The system supports barcode scanning for warehouse operations, eliminating manual data entry errors.

You can set up multiple inventory valuation methods (FIFO, LIFO, AVCO) and track serial numbers or lot numbers for complete product traceability.

The platform’s perpetual inventory system means you always know your exact stock position without conducting time-consuming physical counts. Cycle counting features allow you to verify accuracy section by section, maintaining high reliability without shutting down operations.

Problem 2: Excess Inventory Tying Up Working Capital

The Challenge:

Without proper demand forecasting and reorder point optimization, businesses either overstock (tying up capital in unsold goods) or understock (losing sales). Excess inventory costs companies approximately 25-30% of their total inventory value annually through storage, insurance, and obsolescence.

How Odoo Solves It:

Odoo’s intelligent reordering rules automatically calculate optimal stock levels based on lead times, sales velocity, and seasonality patterns. The system can generate purchase orders automatically when inventory hits minimum thresholds, ensuring you maintain just enough stock without excess.

The forecasting reports analyze historical sales data to predict future demand, helping you make informed purchasing decisions. You can set maximum stock levels to prevent over-ordering and configure different reordering strategies for various product categories—fast-moving items receive different treatment than slow-moving stock.

For manufacturers, Odoo Manufacturing MRP consolidates demand forecasting, inventory management, capacity planning, quality control, and cost analysis into one system, aligning production with realistic inventory needs

Problem 3: Inefficient Purchase Order Management and Supplier Coordination

The Challenge:

Managing multiple suppliers, tracking purchase orders, comparing prices, and ensuring timely deliveries becomes overwhelming as businesses scale. Manual processes lead to duplicate orders, missed deliveries, and poor supplier accountability.

How Odoo Solves It:

Odoo’s Purchase module integrates seamlessly with inventory management, creating a unified procurement workflow. You can store detailed supplier information, including lead times, pricing agreements, and delivery performance metrics. The system automatically suggests the best supplier based on price, delivery time, and historical reliability.

Request for Quotations (RFQs) can be generated and sent to multiple suppliers simultaneously, with responses tracked in one centralized location.

Once orders are placed, the system tracks delivery dates and sends automatic reminders for overdue shipments. Vendor bill management connects directly to accounting, ensuring three-way matching between purchase orders, receipts, and invoices.

Recommended Blogs for You:

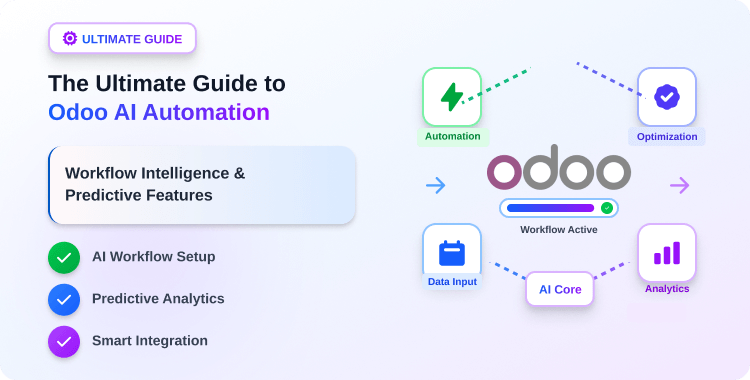

👉 The Ultimate Guide to Odoo AI Automation: Workflow Intelligence & Predictive Features

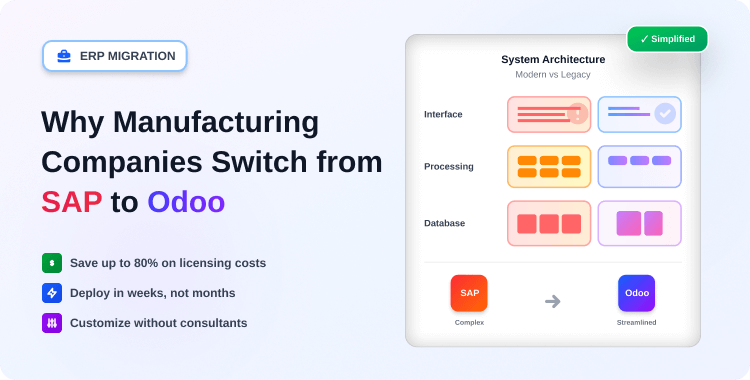

👉 Why Manufacturing Companies Switch from SAP to Odoo: Cost, Speed, and Flexibility That Actually Matters

👉 Top 10 WooCommerce Subscription Mistakes That Quietly Kill Your MRR (And How to Fix Them)

👉 The 5 Hidden Costs of Legacy ERP Systems: Why Businesses Migrate to Odoo

Problem 4: Lack of Visibility Across Multiple Warehouses and Locations

The Challenge:

As businesses expand, managing inventory across multiple warehouses, retail stores, or geographic locations becomes exponentially complex. Without centralized visibility, you can’t efficiently allocate stock, fulfill orders from optimal locations, or transfer inventory between facilities.

How Odoo Solves It:

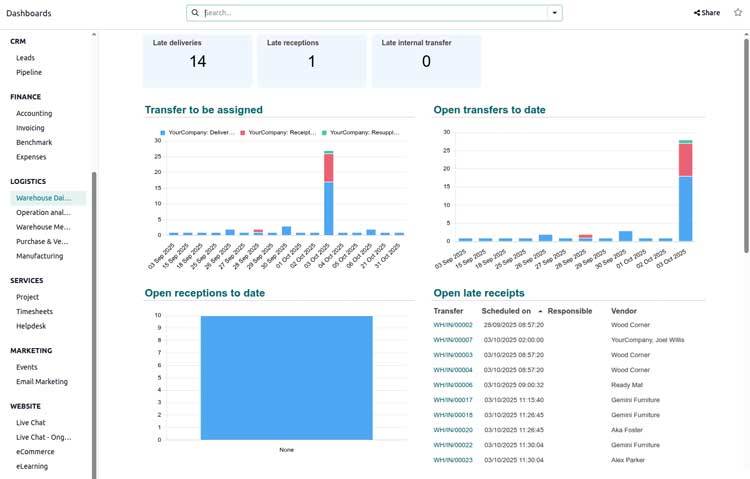

Odoo supports unlimited warehouse locations within a single database, providing complete multi-location inventory management. The system tracks stock levels separately for each location while maintaining centralized visibility through comprehensive dashboards.

Inter-warehouse transfers are streamlined with automated transfer orders and tracking. The system can automatically determine the best fulfillment location based on stock availability and proximity to the customer.

Advanced routing rules allow you to customize how products move through your supply chain, from receiving to quality control to storage to shipping.

You can configure different operational strategies per warehouse, such as cross-docking for high-velocity items or drop-shipping for certain product lines, all managed within the same platform.

Problem 5: Inefficient Warehouse Operations and Picking Processes

The Challenge:

Warehouse workers waste time searching for products, following inefficient picking routes, and dealing with picking errors that require costly returns processing. Poor warehouse organization can reduce productivity by up to 40%.

How Odoo Solves It:

Odoo’s Warehouse Management System (WMS) optimizes every aspect of warehouse operations. The barcode scanning functionality works on any mobile device, allowing workers to receive, pick, pack, and ship products with simple scans that update the system instantly.

The platform supports multiple picking strategies, including wave picking, batch picking, and zone picking, to maximize efficiency. Smart routing algorithms generate optimal picking paths that minimize travel time through the warehouse.

You can implement putaway strategies that automatically assign optimal storage locations based on product characteristics, turnover rates, and storage requirements.

The system tracks warehouse performance metrics like pick rates, accuracy percentages, and fulfillment times, giving you data-driven insights to continuously improve operations.

Problem 6: Poor Demand Forecasting and Seasonal Inventory Planning

The Challenge:

Businesses struggle to accurately predict future demand, especially amid seasonal fluctuations, promotional events, or market volatility. Poor forecasting leads to either stockouts during peak periods or excess inventory during slow seasons.

How Odoo Solves It:

Odoo’s reporting and analytics capabilities provide sophisticated demand forecasting tools that analyze historical sales patterns, identify trends, and account for seasonality. The system can incorporate external factors like promotional calendars or market events into forecasts.

You can run what-if scenarios to plan for different demand situations and adjust inventory levels accordingly. The ABC analysis feature automatically categorizes products by their revenue contribution, allowing you to focus on high-impact items and allocate resources accordingly.

Integration with the sales module means you can factor in pipeline opportunities and upcoming orders when planning inventory levels.

Problem 7: Disconnected Systems Creating Data Silos

The Challenge: When inventory management operates separately from sales, accounting, manufacturing, and e-commerce systems, businesses face constant data reconciliation issues. Information flows break down, causing delays, errors, and missed opportunities.

How Odoo Solves It: Unlike standalone inventory software, Odoo is a fully integrated business management suite where all modules share a single database. When a customer places an order through your Odoo website or POS system, inventory is automatically reserved.

When products ship, accounting entries post automatically. When manufacturing consumes materials, inventory is adjusted in real time.

This seamless integration eliminates double data entry and ensures everyone works from the same accurate information. Sales teams see real-time stock availability during customer conversations.

Accountants access inventory valuation instantly for financial reporting. Manufacturing planners view component availability when scheduling production runs.

The result is faster operations, fewer errors, and better decision-making across your entire organization.

Problem 8: Inability to Track Product Lots, Serial Numbers, and Expiration Dates

The Challenge:

Companies dealing with perishable goods, regulated products, or warranty management need robust traceability. Without proper tracking, they face compliance issues, quality control problems, and an inability to execute effective product recalls.

How Odoo Solves It:

Odoo provides comprehensive lot and serial number tracking throughout the product lifecycle. You can configure which products require tracking and whether to use lot numbers (for bulk items) or unique serial numbers (for individual items).

The system maintains complete traceability from receipt through storage to delivery. If a quality issue arises, you can instantly identify which lot was affected, where it’s located, and which customers received it.

For perishable products, expiration date tracking ensures FIFO rotation and prevents shipping expired goods.

Quality control checkpoints can be configured at receiving, production, and shipping stages, with mobile barcode scanning making inspections quick and documented.

Problem 9: Complex Returns and Reverse Logistics Management

The Challenge:

Processing returns efficiently while maintaining inventory accuracy is notoriously difficult. Poor returns management frustrates customers, creates inventory discrepancies, and complicates accounting reconciliation.

How Odoo Solves It:

Odoo streamlines the entire returns process with dedicated return merchandise authorization (RMA) workflows. When customers initiate returns, the system guides staff through inspection, restocking decisions, and refund or replacement processing.

Smart routing rules determine whether returned items go back to sellable inventory, quarantine for inspection, or scrap disposition. All financial implications flow automatically to accounting, ensuring proper cost allocation.

The system tracks return reasons and patterns, helping you identify quality issues or opportunities to improve product descriptions.

Integration with delivery carriers allows you to generate return shipping labels instantly, improving the customer experience while maintaining visibility throughout the reverse logistics process.

Common Pitfalls in Inventory & Supply Chain Management (And How to Avoid Them)

Even with powerful tools like Odoo, businesses can stumble if they don’t avoid these common mistakes:

- Inadequate Training and Change Management: Implementing sophisticated inventory software without proper staff training leads to underutilization and resistance. Invest time in comprehensive training programs and create clear standard operating procedures. Odoo’s intuitive interface helps, but your team needs to understand both the system and the business processes it supports.

- Poor Master Data Quality: Your inventory system is only as good as your data. Inaccurate product descriptions, missing supplier information, or incorrect reorder points will undermine even the best software. Before implementing Odoo, conduct a thorough data cleansing exercise and establish governance processes to maintain data quality.

- Ignoring the Importance of Physical Audits: While Odoo dramatically improves inventory accuracy, periodic physical counts remain important validation checkpoints. Implement cycle counting programs and investigate discrepancies systematically to continuously improve accuracy.

- Failing to Customize Workflows to Your Business: Odoo offers incredible flexibility, but you need to configure it to match your specific operations. Don’t simply accept default settings—take time to set up warehouse locations, routes, reordering rules, and approval workflows that reflect how your business actually operates.

- Overlooking Integration Opportunities: Odoo’s true power emerges when you leverage integrations across modules. Don’t treat inventory as an isolated function; connect it to your e-commerce platform, accounting system, CRM, and manufacturing operations for maximum efficiency and visibility.

Partner with HasTech IT Limited to Solve Your Top Inventory and Supply Chain Problems with Odoo

As a certified Odoo implementation partner based in Bangladesh, HasTech IT Limited specializes in helping manufacturers, distributors, and retailers solve their top inventory and supply chain problems with a properly implemented Odoo ERP.

We focus on:

- Designing and implementing Odoo inventory and warehouse flows

- Rolling out Odoo‑based supply chain processes for purchasing, logistics, and manufacturing

- Customizing Odoo to match your real‑world operations

- Training your team and providing ongoing support so new processes actually stick

Whether you are just discovering these top inventory and supply chain problems or already know exactly where the bottlenecks are, our certified consultants can help you turn Odoo into a competitive advantage.

Connect with HasTech IT Limited to solve your top inventory and supply chain problems with Odoo.

Frequently Asked Questions

Can Odoo handle multi-currency inventory management?

Yes, Odoo fully supports multi-currency transactions, allowing you to purchase from international suppliers and sell in different currencies while maintaining accurate inventory valuation and financial reporting in your home currency.

Does Odoo work for both manufacturing and retail businesses?

Absolutely. Odoo’s modular design means manufacturers can use the MRP module alongside inventory management for bill of materials and production planning, while retailers leverage POS and e-commerce integrations. For a deeper dive into manufacturing, see the guide on the Odoo Manufacturing MRP module.

How does Odoo compare to standalone inventory software?

Odoo provides inventory management as part of an integrated business suite, eliminating data silos and reducing costs. Standalone solutions may offer more specialized features but require complex integrations with other business systems.

What size warehouse operations can Odoo support effectively?

Odoo scales from small businesses with single locations to enterprises managing dozens of warehouses and millions of SKUs. The Community edition works well for smaller operations, while Enterprise offers advanced features for complex requirements.

Can we migrate our existing inventory data into Odoo?

Yes, Odoo provides data import tools and templates for migrating products, inventory quantities, suppliers, and historical data from spreadsheets or other systems. Professional implementation partners can assist with complex migrations.

Conclusion

Inventory and supply chain challenges don’t have to hold your business back. As we’ve explored throughout this guide, Odoo provides comprehensive, integrated solutions to the most pressing problems facing growing companies, from real-time inventory accuracy and intelligent forecasting to multi-warehouse management and seamless system integration.

The key takeaways? Modern businesses need unified systems that break down data silos, automation that eliminates manual errors, and real-time visibility that empowers better decisions. Odoo delivers all three at a fraction of the cost of traditional enterprise solutions.

Ready to transform your inventory and supply chain management? Start by identifying which of these problems costs your business the most, whether it’s stockouts, excess inventory, or inefficient warehouse operations.

Then explore how Odoo’s specific modules address those pain points. With both Community and Enterprise editions available, there’s a solution that fits your current needs and scales with your growth.

Take action today: explore the Odoo Community edition, or schedule a consultation with HasTech IT Limited to map your top inventory and supply chain problems to a realistic Odoo roadmap.

Our certified Odoo experts in Bangladesh and beyond can help you design, implement, and optimize an ERP that finally puts you back in control of your inventory and supply chain.