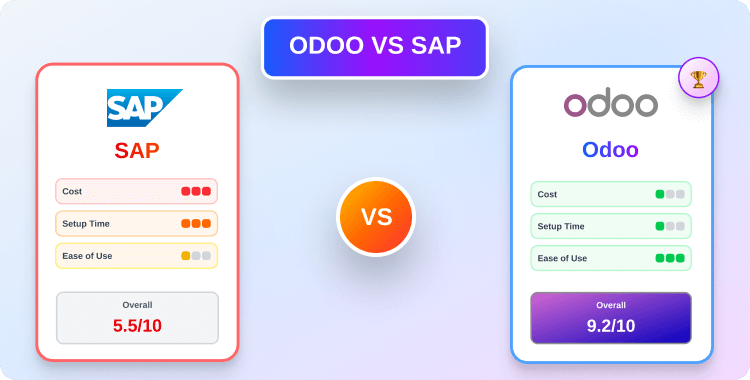

Odoo vs SAP: Manufacturing Feature Comparison & Cost Analysis

Manufacturing executives face a critical decision: should they invest in Odoo or SAP? This question determines not just software capabilities, but also cash flow, implementation risk, and operational agility for the next decade.

The stakes are significant. According to 2024 market data, the global manufacturing software market reached $44.7 billion, growing 10.8% year-over-year.

Within this landscape, SAP leads with 10.2% market share, while Odoo is growing rapidly with 120,729+ active implementations globally. Yet choosing between them means understanding where each platform thrives, and where it stumbles.

This comprehensive guide compares Odoo vs SAP across manufacturing features, pricing models, implementation timelines, and real-world use cases. Whether you operate a 20-person job shop or a 5,000-employee multi-plant manufacturer, you’ll find actionable insights to guide your decision.

Key Takeaways

- Discover the $500K+ annual cost gap between Odoo and SAP

- Learn which manufacturing features each platform excels at delivering

- Find out which ERP fits your production scale, budget, and timeline

- See how real manufacturers chose between these two giants

- Understand TCO drivers beyond licensing fees

Overview of Odoo vs SAP

What Are Odoo and SAP? Defining the Core Contenders

SAP S/4HANA is the enterprise-grade ERP backbone built for large organizations. It powers operations in over 25 industry segments across 130+ countries. SAP’s strength lies in handling complex, multi-entity operations with rigid governance, extensive regulatory compliance, and deep integrations across global supply chains.

Odoo is an open-source, modular ERP platform designed for agility. Instead of forcing organizations into pre-built configurations, Odoo lets you start with one module—say Manufacturing—and add CRM, Accounting, or HR as you grow. Its philosophy centers on “build what you need, pay for what you use.”

The fundamental difference: SAP solves for enterprise complexity; Odoo solves for business flexibility.

Manufacturing Features: Side-by-Side Comparison

Both platforms manage core manufacturing workflows—production planning, material management, quality control, and costing. But their approaches differ significantly.

Production Planning & Scheduling

Odoo 19 Manufacturing features smart production scheduling that dynamically optimizes workload across machines, work centers, and labor. The system automatically adjusts lead times based on live conditions, allows users to merge or split manufacturing orders, and switches suppliers or substitutes materials without manual intervention. Real-world result: reduced idle time and faster order completion.

SAP S/4HANA deploys advanced MRP II with constraint-based logic, capacity planning, and labor scheduling. Research indicates SAP manufacturers reduce order-to-delivery cycle time by 27% and improve on-time delivery by 32% through enhanced visibility and process synchronization. However, configuration is more rigid—optimizing the schedule often requires consultant expertise.

Feature Odoo SAP Production Scheduling Automated, flexible, dynamic Advanced but requires configuration Capacity Planning Visual planning tools Constraint-based optimization BOM Management Simple to multi-level Complex, multi-site multi-product Lead Time Adjustment Automatic based on conditions Manual or parameterized rules

Quality Control & Compliance

Odoo 19 introduces AI-powered quality control that predicts quality failures, suggests preventive actions, and automates corrective alerts.

Work orders include QC checkpoints, barcode scanning for material traceability, and real-time defect tracking tied directly to production orders. This reduces rework and maintains consistent product quality.

SAP emphasizes automated inspections, deviation tracking, and non-conformance reporting, with supplier ratings and internal audits tied to quality metrics.

For regulated industries (pharmaceutical, medical device, aerospace), SAP’s compliance framework is more mature, but setup and ongoing governance require dedicated quality teams.

2026 Update: Both platforms now support digital traceability for quality audits—a requirement under FDA QMSR rules (effective February 2, 2026) for biotech and medical device manufacturers.

Material & Inventory Management

Odoo manages inventory across multiple locations with accurate demand forecasting, master production scheduling (MPS), and automated purchase orders for low-stock items.

Material availability is displayed within manufacturing orders, preventing production delays. The system supports standard and custom BOM structures with automatic cost updates based on component changes.

SAP handles enterprise-scale inventory with multi-site, multi-product BOMs, routing logic, and revision controls. It reduces inventory carrying costs by 20-30% through precise demand forecasting and production scheduling. However, this level of precision requires clean master data and ongoing governance.

Real-Time Costing & Analytics

Odoo calculates real-time costing at the material, labor, and overhead levels. Manufacturing orders show live cost status, enabling managers to catch cost overruns early. Production analytics dashboards display OEE (Overall Equipment Effectiveness), machine downtime, scrap levels, and labor costing.

For detailed insights into how capacity planning integrates with costing to deliver on-time, on-budget manufacturing, read Project Management With Capacity Planning in Odoo ERP: Delivering On Time, On Budget, Every Time.

SAP provides activity-based costing with multi-currency support and intercompany transactions. Advanced analytics tie production metrics to financial performance. Manufacturers using SAP’s analytics achieve 43% reduction in decision latency—the time from identifying an issue to implementing a fix.

Pricing & Total Cost of Ownership (TCO): The Numbers

This is where the decision becomes financial.

Odoo Pricing Breakdown

Community Edition: Free (open-source, ideal for pilot projects)

Standard Edition:

- $24.90/user/month (USD, billed annually)

- Includes all core modules: Manufacturing, Inventory, Accounting, CRM, HR

- Cloud hosting on Odoo Online is included

- No hidden per-module fees

Custom Edition (for enterprises):

- ~$46.80/user/month (Tier-1 countries)

- Includes API access, multi-company support, Odoo.sh dedicated cloud

- Customization assistance available

Implementation & Setup:

- Small to mid-market: $10,000–$80,000 for comprehensive manufacturing rollout

- Typically 4–12 weeks for go-live with moderate customization

Example: A 50-user manufacturing company using Odoo Standard would pay:

- Annual Licensing: 50 users × $24.90 × 12 = $14,940

- Implementation: ~$30,000–$50,000 (one-time)

- 5-Year TCO: ~$100,000–$150,000 (licensing + implementation + minimal support)

SAP Pricing Breakdown

SAP Business One (small to mid-market):

- $1,350–$3,200 per user (one-time license or annual subscription)

- Implementation: $25,000–$150,000 depending on complexity

SAP S/4HANA (enterprise):

- Quote-based pricing; typically $100,000–$500,000+ annually for licensing alone

- Implementation services: $150,000 minimum; complex deployments exceed $1M

- Ongoing maintenance: 15–22% of licensing costs annually

- Average implementation: 12–24 months

Example: A 50-user manufacturing operation using SAP would pay:

- Annual Licensing (Business One): 50 × $1,800 average = $90,000+

- Implementation: ~$80,000–$150,000

- 5-Year TCO: ~$600,000–$1,000,000+ (licensing, implementation, maintenance, consulting)

TCO Comparison

Odoo’s TCO is 5–10x lower than SAP, according to industry benchmarks. For a mid-sized manufacturer (50 users, moderate customization):

- Odoo: $100,000–$200,000 over 5 years

- SAP: $600,000–$1,500,000 over 5 years

- Savings with Odoo: $400,000–$1,300,000

This gap widens for multi-plant or multi-company operations, where SAP licensing multiplies significantly.

Recommended Blogs for You:

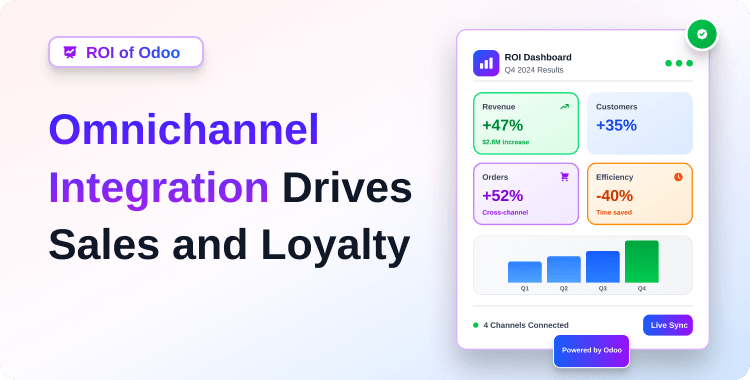

👉 The ROI of Odoo for Retail: Real Numbers on How Omnichannel Integration Drives Sales and Loyalty

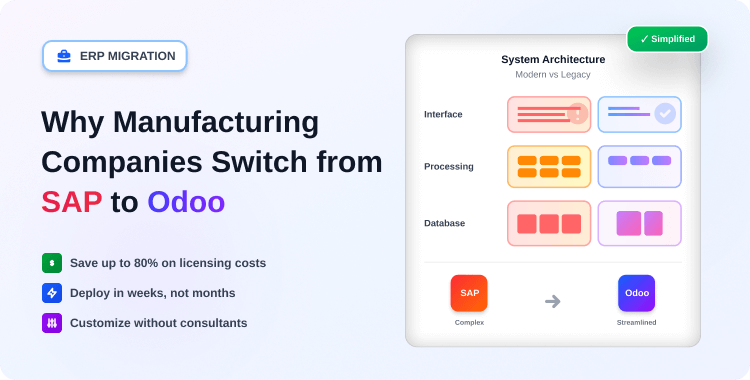

👉 Why Manufacturing Companies Switch from SAP to Odoo: Cost, Speed, and Flexibility That Actually Matters

👉 Manufacturing Excellence: How Odoo MRP Transforms Production Planning and Reduces Costs

👉 Streamline Production with the Odoo Manufacturing MRP Module: The Complete Guide

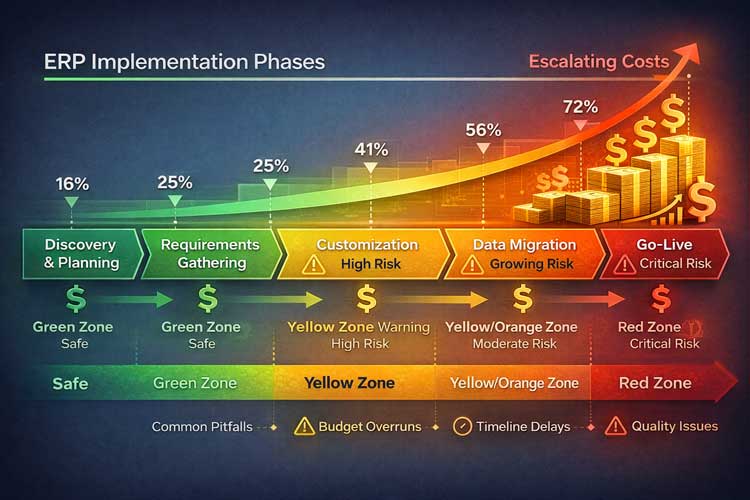

Implementation Timeline: How Fast Can You Go Live?

Implementation speed is a hidden cost driver. Every month of delays costs operations efficiency, delays revenue, and burns consultant and internal resource hours.

Odoo Implementation Timeline

Typical Journey: 4–16 weeks for mid-market manufacturing

- Discovery & Requirements (1–2 weeks)

- Configuration (2–4 weeks): Set up BOMs, work centers, routing, costing

- Data Migration (1–2 weeks): Load products, suppliers, inventory

- Testing & Customization (2–4 weeks): User acceptance testing, minor module adjustments

- Training & Go-Live (1 week): End-user training, parallel run, cutover

Why Odoo is Fast:

- Pre-built modules eliminate development from scratch

- Python-based customizations are faster than SAP’s ABAP

- Fewer integration dependencies in early phases

- Cloud hosting eliminates infrastructure setup

SAP Implementation Timeline

Typical Journey: 12–24 months for enterprise deployments

- Planning & Discovery (2–3 months)

- Detailed Design (2–3 months)

- Development & Configuration (4–6 months)

- System Integration Testing (2–3 months)

- User Acceptance Testing (2–3 months)

- Go-Live Preparation & Training (1–2 months)

- Post-Go-Live Support (3–6 months)

Why SAP Takes Longer:

- Complex enterprise requirements demand extensive upfront design

- ABAP customizations require specialized developers (scarce and expensive)

- Multiple modules (Finance, Supply Chain, Manufacturing) must integrate seamlessly

- Regulatory compliance and audit controls add testing layers

- Multi-site deployments compound complexity

Cost Implication: A 12-month delay in SAP implementation can cost $500K–$2M in lost operational efficiency, deferred benefits, and extended consulting fees.

Choosing the right implementation partner is critical to meet timelines and budgets. Whether you’re a Bangladesh-based manufacturer or working with regional partners, read Odoo ERP Implementation Service Company in Bangladesh for guidance on selecting an implementation team that matches your scope, timeline, and budget constraints.

Real Manufacturing Use Cases: How Companies Chose

Case 1: Sciencix (Laboratory Equipment) – Choose Odoo

Challenge: 600+ SKUs with manual order tracking and inventory visibility. Lead times were unpredictable, and order fulfillment errors damaged customer trust.

Solution: Implemented Odoo Manufacturing, Inventory, eCommerce, and Accounting modules.

Results:

- Automated web order entry directly into ERP

- Inventory accuracy improved to 98%+

- Order fulfillment time cut from 5 days to 2 days

- TCO: ~$35,000 (implementation + first-year licensing)

Why Odoo: Sciencix needed fast time-to-value and couldn’t justify SAP’s six-figure implementation for a lean operation. Odoo’s modular approach lets them start with core workflows and add quality management later.

Case 2: Texas Controls USA (Precision Tools) – Choose Odoo

Challenge: Custom wind turbine tensioners require coordinating project schedules with production capacity. Manual coordination led to missed deadlines.

Solution: Implemented Odoo MRP, Inventory, Sales, and Project Management.

Results:

- Project deadlines aligned with production capacity

- On-time delivery improved from 76% to 94%

- Lead time predictability enabled faster customer quoting

- Implementation: 8 weeks; no integration delays

Why Odoo: SAP’s rigid framework would have forced them to fit their custom workflows into pre-built modules—a mismatch for a precision job shop. Odoo’s flexibility enabled them to build project-to-manufacturing workflows that matched real operations.

Case 3: Large Discrete Manufacturer (500+ users) – Uses SAP

Challenge: Multi-plant operations across three countries, complex regulatory requirements (ISO 9001, ISO 13485), and need for consolidated global financial reporting.

Solution: Implemented SAP S/4HANA with manufacturing, finance, and supply chain modules.

Results:

- Unified global inventory visibility across plants

- Consolidated financial reporting in 48 hours (vs. 2 weeks manual)

- Quality compliance audit preparation: automated, verifiable traceability

- Cost savings: $2M annually from better demand forecasting

Why SAP: At this scale, SAP’s robust governance, multi-entity consolidation, and pre-built compliance frameworks justified the $800K implementation investment. ROI was achieved within 18 months.

Common Pitfalls Strategies

Pitfall 1: Underestimating Customization Costs

With Odoo: Many companies start with the community version or minimal modules, then discover they need custom workflows. Uncontrolled customization can double implementation costs.

This mirrors a broader pattern described in The 5 Hidden Costs of Legacy ERP Systems: Why Businesses Migrate to Odoo, poor ERP implementation planning leads to exponential cost multipliers. Whether using Odoo or any ERP, the solution is the same.

Solution: Define your complete workflow before implementing. Engage end-users early and document all process requirements.

With SAP: Over-customization is the norm. “We’ve never seen SAP without customization,” consultants often say. Adding custom logic to SAP locks you into a vendor relationship; every upgrade becomes costly.

Solution: Use SAP’s standard processes as much as possible. Accept slight inefficiencies to avoid customization debt.

Pitfall 2: Poor Data Migration

With Both: Dirty legacy data ruins any ERP. Duplicates, inconsistent naming, and incomplete BOMs cause months of firefighting post-go-live. Solution: Invest in data cleansing before migration. Budget 10–15% of implementation costs for this.

Pitfall 3: Insufficient Change Management

With Both: Users trained on system features but not on new processes fail to adopt the ERP. Manual workarounds persist, defeating the business case. Solution: Create a detailed process redesign plan before you configure the system. Assign process owners, not just IT teams.

Advanced Strategy: Phased Rollout

For Odoo: Start with Manufacturing + Inventory. Go live in 8 weeks. Add Quality and Maintenance 3 months later. This phased approach keeps initial risk low and builds team confidence.

For SAP: Design the full enterprise architecture upfront (12+ weeks), but deploy in waves—Plant A first, then B, then C. Each wave builds on lessons learned, reducing go-live risk.

Usability & User Experience: Which Platform Is Easier?

Odoo User Interface

Modern, Intuitive Design: Inspired by consumer SaaS tools (Notion, Monday.com), Odoo’s interface uses:

- Drag-and-drop workflows

- Visual dashboards with 1-click filtering

- Mobile-responsive design for shop floor access

- Minimal training required; most users become productive in 2–3 hours

Downside: Limited customization of screen layouts without coding.

SAP Fiori User Interface

Structured, Role-Based: SAP’s Fiori modernization improved usability, but

- Still denser than consumer-grade tools

- Requires training; typical mastery: 2–3 weeks

- Role-based apps mean users see only their workflow

- Excellent for structured, repeatable processes

Verdict: Odoo wins on ease-of-use; SAP wins on control and consistency.

Integration Capabilities & Ecosystem

Odoo Integrations

- 20,000+ modules in the Odoo Apps Store

- Native integrations with Stripe, Amazon, Shopify, Salesforce

- Open APIs enable custom integrations without licensing fees

- Community-built connectors for legacy systems

- Cost: $0–$5,000 per integration (typically)

For manufacturers selling directly through eCommerce channels, seamless order and inventory integration is critical.

Discover how to automate the entire order-to-fulfillment cycle in Odoo eCommerce ERP Integration: Automating Orders, Inventory, and Payments for Scalable Growth.

SAP Integrations

- Integrations via SAP Business Technology Platform (SAP BTP)

- Robust ecosystem, but often requires SAP consulting partners

- Integration complexity necessitates consulting: $50K–$200K per major integration

- Mature connectors to legacy systems and modern cloud tools

- Cost: $50K–$500K+ per major integration

Winner for SMBs: Odoo (lower integration cost, faster deployment)

Winner for Enterprises: SAP (more mature integrations, higher control)

Security, Compliance & Data Governance

Odoo Security Model

- Open-source code enables community security audits

- Cloud hosting on Odoo Online uses ISO 27001-certified infrastructure

- Role-based access controls (RBAC) with fine-grained permissions

- Audit logs for all transactions

- Data residency options: EU, US, or on-premise

- Compliance: GDPR, SOC 2, ISO 27001

Consideration: Community Edition requires your own security governance; some organizations avoid this due to liability concerns.

SAP Security Model

- Enterprise-grade security built for regulated industries

- Role-based access with segregation of duties (SOD) checks

- Automated compliance controls for HIPAA, FDA, SOX, etc.

- Encrypted connections, federated identity management

- Audit trails with tamper-proof logging

- Compliance: HIPAA, FDA CFR Part 11, SOX, ISO 27001

Advantage: SAP’s compliance framework is pre-built for regulated industries. Medical device, pharma, and financial services manufacturers often choose SAP specifically for this.

Verdict: For compliance-heavy industries, SAP is safer; for most manufacturing, Odoo’s security is sufficient.

Frequently Asked Questions

Q: Which ERP should a small manufacturer (under 50 users) choose?

A: Odoo is the clear winner for small manufacturers. Cost is 80–90% lower, implementation is 4–8x faster, and the modular approach lets you start with just Manufacturing + Inventory. SAP is overkill at this scale; you’ll pay for enterprise features you don’t use. Start with Odoo Community Edition as a pilot—it’s free.

Q. Does SAP offer better analytics than Odoo for manufacturing KPIs?

A: SAP’s analytics are more mature and enterprise-focused. If you need consolidated multi-plant dashboards, predictive forecasting, or complex variance analysis across 10+ legal entities, SAP’s advantage is clear. Odoo’s dashboards are excellent for single-plant or small multi-plant operations, but custom BI integration (Power BI, Tableau) is needed for advanced analytics. For manufacturing-specific KPIs (OEE, scrap rate, on-time delivery), both are capable.

Q: Can we migrate from Odoo to SAP later without starting over?

A: Yes, but it’s complex and expensive. Plan for 6–12 months and $200K–$500K in data migration and retraining costs. The better strategy: choose your platform based on your 5-year roadmap. If you’ll outgrow Odoo (multi-country, 500+ users, complex consolidated reporting), start with SAP. If you’re building a lean, nimble operation, commit to Odoo and scale it.

Q. Which platform handles multi-plant manufacturing better?

A: Both handle it, but differently. SAP excels at consolidated reporting, regulatory compliance across plants, and global supply chain visibility. Odoo works well for 2–5 plants with standard processes; beyond that, centralized control becomes complex. Consider your integration needs: SAP’s strength is connecting far-flung operations; Odoo’s strength is flexibility within each plant.

How long do typical manufacturing implementations take with each platform?

Odoo: 4–16 weeks for go-live (standard manufacturing)

SAP: 12–24 months for enterprise (large multi-plant deployments can exceed 24 months)

This gap means Odoo can start delivering ROI 6–12 months before SAP goes live.

What’s the best use case for each platform?

Odoo: Custom job shops, mid-market manufacturers, companies needing fast ROI, and those with limited IT staff.

SAP: Global enterprises, regulated industries, complex multi-entity operations, and companies where cost is secondary to control and compliance.

Conclusion: Choosing Your Manufacturing ERP

The decision between Odoo vs SAP is not about which is “better”, it’s about which fits your operational model, budget, and growth trajectory.

Choose Odoo if you:

- Operate a lean, agile manufacturing business (under 200 users)

- Need fast implementation (weeks, not months)

- Want to control costs (80–90% lower TCO)

- Value flexibility over rigid governance

- Plan to manage the system with a small internal team

Choose SAP if you:

- Run a global, multi-plant operation (500+ users)

- Require rigid compliance frameworks (pharmaceutical, medical device, defense)

- Need consolidated financial reporting across entities

- Have a budget for a 12–24 month implementation

- Prioritize control and audit trails over speed

The Middle Path: Many manufacturers start with Odoo, prove ROI quickly, and later migrate to SAP as they scale. This phased approach manages risk, builds internal ERP expertise, and demonstrates value to executive stakeholders.

For manufacturing, 2026 is the year of digital transformation. Whether you choose Odoo or SAP, the imperative is clear: move away from spreadsheets and disconnected systems. Real-time visibility, predictive planning, and integrated quality management are no longer optional, they’re competitive requirements.

Your next step: Define your 5-year manufacturing roadmap. Will you grow from 30 users to 50? From one plant to three? Are regulatory requirements part of your landscape? Answer these questions, and the ERP choice becomes obvious.