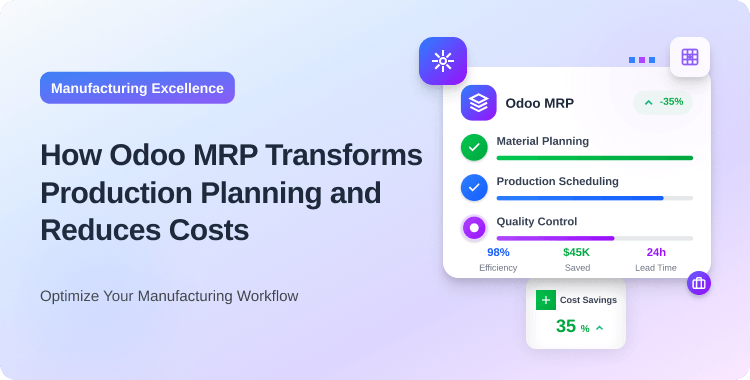

Manufacturing Excellence: How Odoo MRP Transforms Production Planning and Reduces Costs

Imagine running a factory where everything works like clockwork.

Your team knows exactly what materials to order, when machines need to run, and how much inventory to keep. There’s no guessing, no wasted time, and no expensive delays.

This isn’t a dream for modern manufacturers anymore. It’s the power of MRP (Material Requirements Planning) combined with Odoo’s manufacturing system.

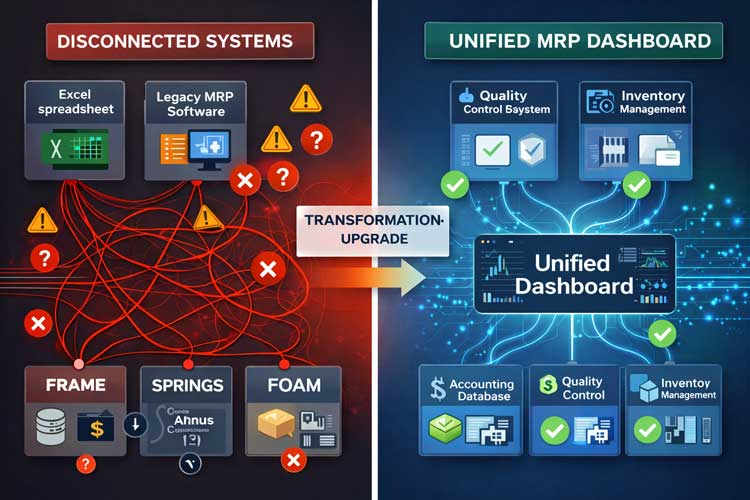

Let me tell you a real story. A German automotive company with 2,500 employees faced a huge problem: they used old spreadsheets, disconnected systems, and manual work orders. Their inventory accuracy was only 70%, and they were losing money every day.

Then they switched to Odoo MRP. Within months, their inventory accuracy jumped to 98%. Their production downtime dropped by 66%. And most importantly? They cut operational costs by 30%.

That’s the transformation we’re talking about today.

In this guide, we’ll show you exactly how MRP transforms production planning and why smart manufacturers are making this shift right now.

Key Takeaways

- MRP transforms production planning through real-time automation

- Reduce inventory costs and production downtime simultaneously

- 30% operational cost reduction proven in real case studies

- Bill of materials and demand forecasting eliminate production guesswork

- Odoo MRP scales with your manufacturing growth from day one

ShopLentor- WooCommerce Builder for Elementor & Gutenberg

A versatile page builder to build modern and excellent online stores with more than 100k+ Active Installations.

Understanding Material Requirements Planning (MRP)

What Exactly Is MRP?

MRP stands for Material Requirements Planning. It’s a smart system that figures out exactly what materials and parts you need to make your products.

Instead of guessing or using old spreadsheets, MRP calculates everything based on real customer demand. It tells you: “You need 500 units of Part A on Tuesday, 300 units of Part B on Wednesday.”

Think of it like a recipe. If you’re making 100 cakes, you don’t guess how much flour to buy.

You calculate: 100 cakes × 2 cups flour per cake = 200 cups flour needed.

MRP does this automatically for all your products and parts.

Why Production Planning Matters Now

Manufacturing today is complicated. You have multiple products, complex supply chains, and customers who want everything yesterday.

Bad production planning costs you money. When you:

- Order too much inventory, and cash sits idle

- Order too little, production stops

- Can’t find the right parts, orders get delayed

- Don’t coordinate with suppliers, rush fees pile up

Good production planning stops all these problems. It’s the backbone of modern manufacturing excellence.

The Three Core Goals of MRP

1. Prevent Stockouts: Always have the parts you need when you need them.

2. Minimize Excess Inventory: Don’t buy more than necessary; it wastes money.

3. Keep Costs Low: Buy smart, produce efficiently, reduce waste.

The Definitive Guide to How MRP Transforms Production Planning

Real-Time Visibility: From Data Silos to Unified Production Intelligence

Most manufacturers struggle with disconnected systems. Someone checks inventory in one system, production schedules in another, and supplier orders in a third.

This creates data silos – separate information that doesn’t talk to each other.

MRP solves this with one unified dashboard. You see everything in one place:

- How many raw materials do you have right now

- What’s currently being produced

- When will supplier orders arrive

- Which orders are delayed

A production planner no longer spends 2 hours hunting through different systems. They open one dashboard and know the entire situation in seconds.

Real result: One manufacturer cut planning time by 50%. Another team member can now do what used to take three people.

Automated Demand Forecasting: Eliminating Production Guesswork

Guessing how much to produce is dangerous. You either make too much or too little.

MRP uses data-driven demand forecasting. It looks at:

- Past sales patterns

- Current market trends

- Customer orders on the books

- Seasonal changes

The system then predicts: “Based on history and current orders, you’ll need 5,000 units next month.”

This isn’t a guess. It’s based on real data.

Smart reorder points make it even better. The system automatically tells your team: “When inventory drops to 1,000 units, place a new order.” You never run out. You never order too much.

Real benefit: Studies show that companies that use automated forecasting improve production efficiency by 15-25% in the first year.

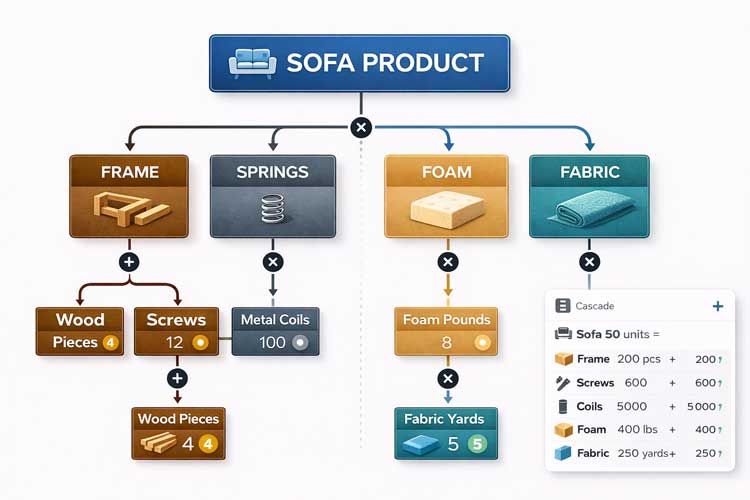

Bill of Materials (BOM) Explosion: Multi-Level Production Planning

Complex products need complex planning. A car engine has hundreds of parts. An industrial machine has thousands.

Manually tracking all these parts? Impossible without mistakes.

This is where the Bill of Materials (BOM) explosion comes in. Your BOM is like a recipe with nested steps.

Example: To build a sofa, you need:

- Frame (made from 4 wood pieces + 12 screws)

- Springs (100 coils per sofa)

- Foam (8 pounds per sofa)

- Fabric (5 yards per sofa)

When you enter “build 50 sofas,” MRP automatically explodes this BOM. It calculates:

- 200 wood pieces needed

- 600 screws needed

- 5,000 coils needed

- 400 pounds of foam

- 250 yards of fabric

And it schedules procurement for each item based on supplier lead times.

No more partial production runs. No more waiting for the last component.

Recommended Blogs for You:

👉 Top 10 Software Development Companies in Bangladesh 2026: Complete Guide

👉 Odoo vs SAP: Manufacturing Feature Comparison & Cost Analysis

👉 Project Management With Capacity Planning in Odoo ERP: Delivering On Time, On Budget, Every Time

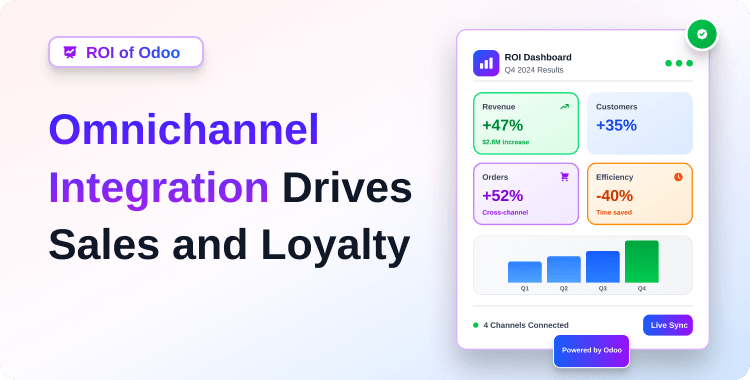

👉 The ROI of Odoo for Retail: Real Numbers on How Omnichannel Integration Drives Sales and Loyalty

Production Scheduling & Capacity Planning: Eliminating Bottlenecks

Your factory has limited machine capacity and limited workers. Without smart scheduling, bottlenecks happen constantly.

One machine becomes the slowest point. Everything backs up. Nothing gets done on time.

MRP prevents this through intelligent capacity planning. It asks:

- Which machines do we have?

- What’s their capacity?

- How long does each job take?

- What’s the best order to schedule jobs?

The system then creates an optimized production schedule that uses every machine efficiently.

Real-world result: A German automotive parts manufacturer reduced production downtime by 66% (from 12 hours per month to just 4 hours). Why? Better scheduling eliminated idle time and rework.

Inventory Optimization & Cost Reduction Through MRP

Here’s where MRP saves serious money.

Carrying too much inventory is expensive. You pay for:

- Warehouse space

- Security and maintenance

- Potential obsolescence (parts that never get used)

- Insurance

Carrying too little inventory is also expensive. You pay for:

- Emergency expedited shipping

- Stopping production lines

- Unhappy customers

- Lost sales

MRP finds the perfect balance. It maintains optimal inventory levels by syncing production with actual demand.

The German automotive company improved its inventory accuracy from 70% to 98%. This alone freed up millions in cash.

Real numbers: That company cut total operational costs by 30%. How?

- 28% better inventory accuracy = less wasted stock

- 66% less production downtime = more output with same resources

- 43% faster order fulfillment = happier customers, repeat business

Lead Time Reduction & Faster Time-to-Delivery

In manufacturing, speed matters. Customers want their orders fast.

With manual production planning, lead times drag on. Everything takes longer because:

- Information moves slowly

- Decisions get delayed

- Materials arrive late

- Production stops waiting

MRP cuts through all this. Real-time visibility and automated scheduling mean:

- Materials arrive exactly when needed

- Production flows without interruption

- Orders ship faster

The German auto parts company reduced order fulfillment time by 43% (from 7 days to 4 days).

Why this matters: Shorter lead times mean you win more business. Customers choose the faster supplier. It’s that simple.

Quality Control Integration: Preventing Defects Before They Occur

Quality problems are expensive. When a defective part reaches a customer:

- They stop production

- They send it back

- You have to remake it

- You lose their trust

Better to catch problems early.

Modern MRP systems like Odoo integrate quality control checks. When a defect is spotted, the system automatically:

- Flags the issue

- Stops that batch from moving forward

- Alerts the team to fix it

- Records what went wrong

Over time, you see patterns. “Machine 3 produces defects on Tuesdays.” Now you can investigate and fix the root cause.

Result: Fewer defects, less rework, lower costs, happier customers.

Seamless Integration With Accounting & Finance

Here’s a problem most manufacturers face: MRP data and accounting data don’t match.

Production says the cost was $5 per unit. Accounting says it was $7. Who’s right? Nobody knows.

Odoo solves this by integrating everything. When you log materials into production, they automatically flow to accounting. When production finishes, costs auto-calculate.

Now your CFO can answer instantly:

- What was the real cost of that product?

- Are we making money on each product line?

- Should we raise prices?

This real-time financial visibility helps you make better business decisions.

Scalability & Flexibility for Growth

Many manufacturers start with simple spreadsheets. As they grow, they realize spreadsheets don’t scale.

They need a real system. But most traditional ERP systems are expensive, rigid, and take years to implement.

Odoo is different. You start with what you need (MRP + Inventory + Accounting). As you grow, you add more modules:

- Quality control

- Maintenance management

- Advanced planning

The system grows with your business. No expensive rip-and-replace. No year-long implementation nightmare.

Common Pitfalls to Avoid & Advanced MRP Strategies

Pitfall #1: Poor Data Quality Ruins Everything

Garbage in, garbage out. This is the golden rule of MRP.

If your BOM data is wrong, your inventory counts are wrong, or your lead times are guessed, MRP will make bad decisions based on bad data.

Before implementing MRP, clean your data. Verify:

- Every BOM is accurate

- Inventory counts match reality

- Lead times are realistic

- Supplier information is current

One company skipped this step. They implemented MRP with messy data and spent months fixing problems that shouldn’t have existed.

Pitfall #2: Over-Reliance on Forecasts Without Safety Stock

MRP forecasts are smart, but they’re not perfect. Demand surprises happen. Suppliers are sometimes late.

This is why safety stock exists. It’s extra inventory you keep as a buffer against the unexpected.

The trick is calculating the right amount. Too much safety stock and you’re back to carrying excessive inventory. Too little and you run out during surprises.

Advanced manufacturers use DDMRP (Demand-Driven MRP). This adjusts safety stock levels dynamically based on actual demand patterns. It’s smarter than static calculations.

Advanced Strategy: Lean Manufacturing + MRP

Lean manufacturing focuses on eliminating waste. MRP provides the data and automation to make lean work at scale.

Together, they’re powerful:

- MRP prevents overproduction (Lean principle #1)

- Kanban systems (a Lean tool) integrate with MRP for automatic reordering

- Less inventory = Lean efficiency

- Better scheduling = Less idle time = Lean flow

Companies combining Lean + MRP see compounding benefits that neither system alone could achieve.

Advanced Strategy: Predictive Maintenance Through IoT

Modern factories have IoT sensors on machines that report:

- Temperature, vibration, and noise

- Production output and quality metrics

- Hours of operation and maintenance history

When combined with MRP, these sensors prevent unexpected downtime.

The system predicts: “Machine 3’s vibration is increasing. Schedule maintenance in 2 days before it fails.” No surprise breakdowns. No emergency repairs. Production stays on schedule.

Frequently Asked Questions

Q: What is MRP in production planning?

A: MRP (Material Requirements Planning) calculates exactly what materials and components you need based on customer demand. It schedules procurement, production, and inventory automatically to prevent stockouts while minimizing excess inventory.

Q: How much can MRP reduce manufacturing costs?

A: Real-world studies show 15-25% operational efficiency improvements in year one. Case studies document 30% total cost reduction through inventory optimization, reduced downtime, and minimized waste. Payback periods typically range from 1-3 years.

Q: Does Odoo MRP work for small manufacturers?

A: Yes, absolutely. Odoo’s modular approach lets small manufacturers start with just MRP, Inventory, and Accounting modules. As you grow, add more modules. Lower licensing and faster implementation costs make it ideal for SMEs.

Q: How does MRP reduce production lead times?

A: MRP automates scheduling, prevents bottlenecks through capacity planning, eliminates guesswork in material sourcing, and enables parallel processing. Result: faster order-to-delivery cycles and improved customer satisfaction.

Q: What’s the real ROI of implementing MRP?

A: Typical ROI is 15-25% efficiency gains in year one. Cost reduction benefits (lower inventory, less labor, fewer expedited shipments) justify implementation within 12-24 months. Revenue gains from faster delivery and fewer delays compound the ROI further.

Real Case Study: German Automotive Manufacturer

Let’s look at a real company that transformed its manufacturing with Odoo MRP.

The Challenge

This German automotive company supplies parts to major OEMs worldwide. With 2,500 employees, they were drowning in operational complexity.

Their problems:

- Inventory accuracy was only 70% (parts were lost or miscounted)

- Production downtime averaged 12 hours per month

- Orders took 7 days from receipt to fulfillment

- 80% of their processes required manual work

- Data lived in disconnected systems (Excel, legacy MRP, accounting)

The Solution

They implemented Odoo MRP with full integration:

- Unified dashboard connecting inventory, production, and accounting.

- Automated demand forecasting for accurate planning.

- Integrated quality control catches defects early.

- Real-time scheduling prevents bottlenecks.

- Automatic data flow from production to accounting.

The Results

| Metric | Before | After | Improvement |

| Inventory Accuracy | 70% | 98% | +28% |

| Production Downtime | 12 hrs/month | 4 hrs/month | -66% |

| Operational Costs | Baseline | -30% | 30% Reduction |

| Order Fulfillment Time | 7 days | 4 days | -43% |

| Manual Tasks | 80% | <20% | -60% |

What They Said

“Thanks to Odoo MRP, we now have real-time control over our shop floor and inventory. The 30% savings in operational costs were beyond our expectations.”

Key Insights for Your Manufacturing Business

1. Unified systems beat disconnected data. When your MRP, inventory, accounting, and quality systems don’t talk to each other, you lose efficiency and money.

2. Real-time visibility enables better decisions. Dashboards that show live inventory, production status, and supplier lead times eliminate guesswork.

3. Automation frees your best people. When computers handle scheduling and forecasting, your team focuses on strategy and problem-solving instead of data entry.

4. Small improvements compound into big savings. Reducing inventory by 10% here, cutting lead time by 20% there, eliminating one hour of downtime – these add up to 30% cost reduction.

5. You don’t need an expensive, complex system. Odoo proves that manufacturers of any size can access world-class production planning without breaking the bank.

Partnering With HasTech

If you’re a manufacturing business looking to transform operations through an Odoo MRP implementation—especially if you also sell through eCommerce channels—HasTech IT Limited provides expert guidance and comprehensive implementation services.

Why Manufacturers Should Consider Certified Partners

- Risk Reduction: Improper MRP implementation can disrupt production. Certified partners reduce implementation risk through proven methodologies.

- Timeline Acceleration: Expert implementation saves weeks compared to learning Odoo from scratch. ROI often begins within 3-6 months.

- Customization & Integration: Partners ensure Odoo fits your specific manufacturing needs and integrates seamlessly with existing systems.

- Staff Adoption: Partners provide training and change management, ensuring your team adopts the system effectively.

- Ongoing Support: Post-launch optimization ensures you capture full value from your Odoo investment.

Contact HasTech IT Limited

Company: HasTech IT Limited

Website: hastechit.com

Services: Odoo ERP Implementation, Manufacturing Automation, eCommerce Integration, Supply Chain Management

Specialization: Manufacturing-to-eCommerce integration, Bangladesh-specific compliance

Team: 45+ certified Odoo consultants and developers

Certification: Official Odoo Partner

Odoo Partner Directory Link: View HasTech IT Limited – Certified Odoo Partner

Get Expert Guidance:

- Schedule a free consultation to assess your manufacturing operation

- Understand how Odoo MRP would transform your business

- Get transparent pricing and implementation timeline

- See how integrated manufacturing-to-eCommerce systems work

Conclusion: Transform Your Production Planning Today

MRP isn’t a luxury anymore. It’s a necessity for manufacturing excellence.

The companies winning today aren’t those with the most machines or the biggest budgets. They’re the ones using smart systems to optimize every dollar spent on materials, every minute of machine time, and every worker’s effort.

The transformation doesn’t happen overnight. But it happens faster than you’d expect.

Within months, your team will wonder how they ever worked without real-time visibility. Within a year, your costs will drop, your delivery times will improve, and your customers will be happier.

Ready to transform your production planning?

The real case studies prove it works. The German automotive manufacturer cut costs by 30%. Their inventory accuracy jumped from 70% to 98%. Order fulfillment improved by 43%.

Your manufacturing business can achieve the same results.